Table of Contents

Introduction

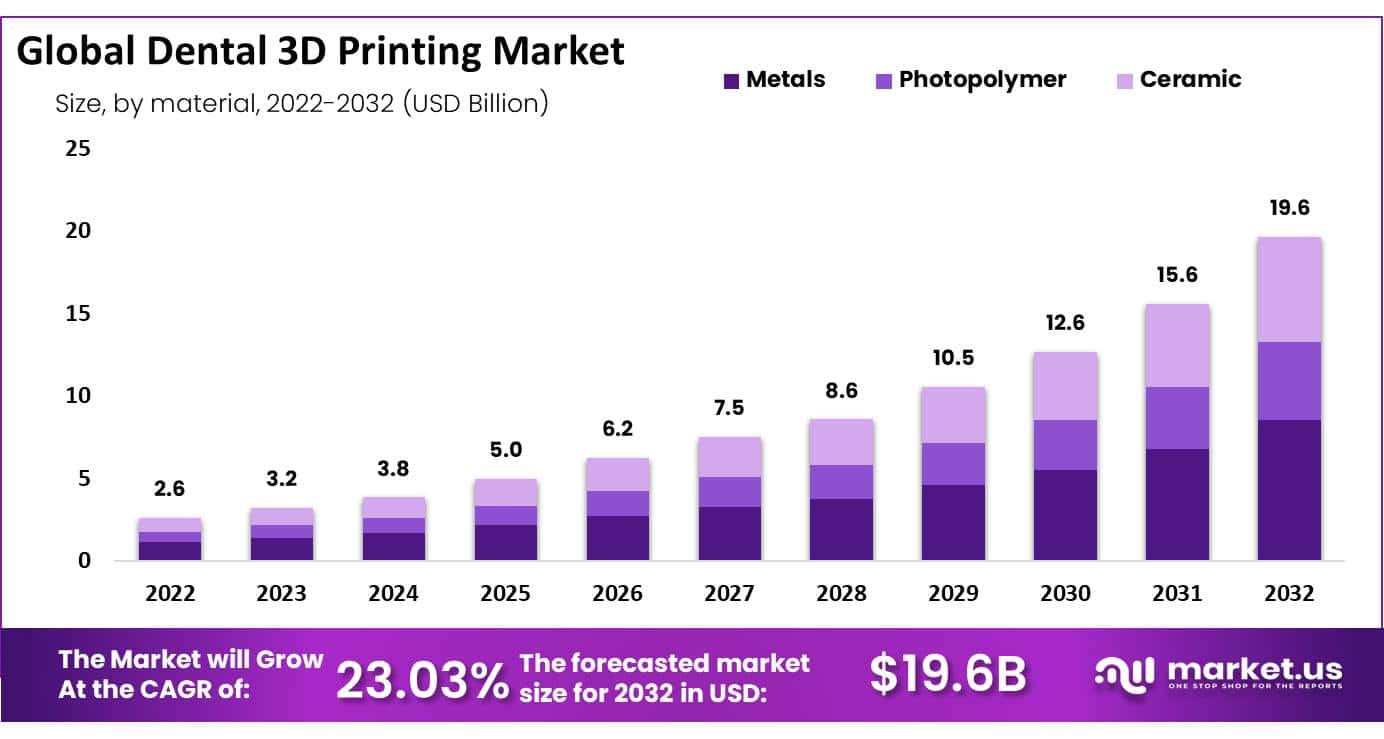

The Global Dental 3D Printing Market is anticipated to expand significantly, reaching an estimated USD 19.6 billion by 2032 from USD 2.6 billion in 2022, at a compound annual growth rate (CAGR) of 23.03% from 2023 to 2032. This growth is fueled by advancements in 3D printing technology, which enhances the precision and reduces the cost of dental devices like implants and crowns. The adoption of new bioprinting techniques allows for more complex and tailored dental solutions, broadening the scope of applications in the field.

Dental practices and hospitals are increasingly incorporating 3D printing technologies to improve service delivery. This shift is largely driven by the ability of 3D printers to quickly produce dental appliances onsite, significantly cutting down patient wait times and streamlining treatment processes. Furthermore, the regulatory landscape has evolved to be more supportive, with entities like the FDA approving numerous dental products made through 3D printing, which bolsters healthcare providers’ confidence in adopting these technologies.

Educational institutions and research facilities are also leveraging 3D printing for training and development purposes. Dental models produced via 3D printing are being used extensively for educational and practical training, enhancing the learning experiences of dental students and professionals alike. Additionally, the cost-effectiveness of 3D printing is another compelling factor, as it eliminates the need for costly tooling and materials, making it an economically viable option for producing high-quality dental products.

Recent strategic partnerships and technological advancements are set to transform the landscape of digital dentistry. In June 2024, 3D Systems secured a significant multi-year purchase agreement with Align Technology, worth around $250 million, to use large-format stereolithography machines for producing clear aligners. This collaboration aims to produce over one million patient-specific aligners daily, underscoring the scale and precision achievable with modern 3D printing technology.

Other noteworthy developments include Dentsply Sirona’s acquisition of a 3D printing startup in November 2023, aimed at enhancing its digital dentistry solutions, and the introduction of the Envision One cDLM dental 3D printer by EnvisionTEC in February 2023. Designed for dental labs and clinics, this printer enhances both speed and accuracy in the creation of dental applications, promising increased productivity and precision in dental treatments. These initiatives reflect the dynamic growth and innovative progress within the dental 3D printing market, highlighting its potential to revolutionize dental care practices.

Key Takeaways

- The dental 3D printing market expanded from USD 2.6 billion in 2022 to a projected USD 19.6 billion by 2032, with a CAGR of 23.03%.

- In 2022, metals were the primary materials in dental 3D printing, accounting for 43.5% of the market’s revenue.

- Selective laser sintering was the leading technology, capturing 37.9% of the revenue in the dental 3D printing sector.

- Orthodontics was the top application in dental 3D printing, representing 39.0% of the market revenue in 2022.

- Dental laboratories were the main end-users, holding 55.5% of the market revenue in 2022.

- North America led in revenue share at 38.9%, with the United States playing a significant role in the market’s growth.

Dental 3D Printing Statistics

- Market Size in 2022: The dental 3D printing market was valued at $2.6 billion in 2022.

- Market Size in 2023: In 2023, the market size increased to $3.2 billion.

- Market Size in 2024: The market is projected to reach $3.8 billion in 2024.

- Market Size in 2025: The forecast for 2025 indicates a market size of $5.0 billion.

- Market Size in 2026: The dental 3D printing market is expected to grow to $6.2 billion in 2026.

- Market Size in 2027: By 2027, the market is forecasted to be $7.5 billion.

- Market Size in 2028: The market size is projected to reach $8.6 billion in 2028.

- Market Size in 2029: The market is expected to grow further to $10.5 billion in 2029.

- Market Size in 2030: The forecast for 2030 shows a market size of $12.6 billion.

- Market Size in 2031: The market is projected to reach $15.6 billion in 2031.

- Market Size in 2032: By 2032, the dental 3D printing market is expected to be valued at $19.6 billion.

- Compound Annual Growth Rate (CAGR): The market is anticipated to grow at a CAGR of 23.03% from 2022 to 2032.

Emerging Trends

- Multi-material Printing: Dental 3D printing technology is advancing rapidly with the introduction of multi-material printing capabilities. This trend allows dental professionals to create complex dental models using different materials simultaneously. By integrating multiple materials in a single print, dental models can now exhibit varied properties, enhancing both their functionality and aesthetic appeal. For instance, one section of a model can be printed to mimic the hardness of enamel, while another part can replicate the softness of gum tissue. This innovation not only improves the quality of dental prosthetics but also streamlines the production process, making it more efficient and cost-effective for dental practices.

- Increased Printing Speed: Recent advancements in 3D printing technology have significantly increased the speed at which dental models and prosthetics can be produced. New systems are now capable of operating up to 10 times faster than older models, allowing dental practices to offer quicker turnaround times for patients. This reduction in production time is especially valuable in clinical settings where timely, personalized dental solutions are essential. Faster printing speeds also mean that dental laboratories can handle higher volumes of work, improving overall efficiency and reducing the time patients spend waiting for their custom dental devices.

- Volumetric Printing: Volumetric printing represents a significant departure from the traditional layer-by-layer approach in 3D printing. This emerging trend enables the creation of dental models in a fully three-dimensional process, eliminating the need for support structures that are typically required in conventional 3D printing. By doing so, volumetric printing reduces material waste and simplifies the post-processing stage, making the overall production process more efficient. This technology has the potential to revolutionize the dental industry by providing faster, more precise, and cost-effective solutions for creating complex dental structures, further pushing the boundaries of what is possible with 3D printing in dentistry.

Use Cases

- Custom Dental Implants and Prosthetics: 3D printing is revolutionizing dentistry by allowing for the creation of custom dental implants and prosthetics. This technology enables dentists to produce implants that are tailored to fit the specific anatomy of each patient. The precision of 3D printing ensures that these implants are comfortable, effective, and durable. Patients benefit from quicker procedures and more personalized care. Furthermore, this customization reduces the need for adjustments and follow-up appointments, as the implants fit better from the start. As a result, 3D printing improves both the efficiency and the outcomes of dental treatments.

- Educational Models and Tools: Dental schools and training programs are increasingly adopting 3D printing to create educational models and tools. These 3D printed models offer students realistic, hands-on experience in a controlled learning environment. Instead of relying solely on theoretical knowledge, students can practice and refine their skills using these models. This approach enhances the learning process, making it more interactive and effective. Additionally, 3D printed models can replicate complex dental cases, preparing students for real-world scenarios. This use of technology bridges the gap between traditional education and practical application.

- Innovative Dental Solutions: Advanced 3D printing techniques are opening new possibilities in the creation of complex dental solutions. For instance, 3D printing is being used to produce volumetric constructs of teeth and gums, which can be vital in reconstructive surgeries and rehabilitation. These intricate models help dentists plan and execute surgeries with greater precision. Additionally, 3D printing allows for the exploration of innovative materials and designs that were previously impossible. This innovation in dental solutions is pushing the boundaries of what is achievable, leading to better patient outcomes and more effective treatments.

- Rapid Prototyping: In dental practices and laboratories, 3D printing is becoming a valuable tool for rapid prototyping. This process allows for the quick creation and testing of new dental devices and tools. By using 3D printing, dentists can iterate and refine their designs based on real-world feedback and testing. This accelerates the development of new products, reducing time to market and improving the quality of dental tools. Rapid prototyping also allows for more experimentation with innovative designs, leading to advancements in dental technology that benefit both practitioners and patients.

Conclusion

The Dental 3D Printing Market is poised for significant growth, driven by technological advancements that enhance precision and reduce costs. The adoption of 3D printing in dental practices and hospitals is transforming patient care by speeding up production and improving customization. Additionally, supportive regulatory changes and strategic partnerships are accelerating market expansion. As 3D printing technology continues to evolve, its applications in dental education, rapid prototyping, and innovative dental solutions will further enhance the industry’s capabilities. The market’s growth is a testament to the increasing demand for efficient, personalized dental care, positioning 3D printing as a key player in the future of dentistry.

Discuss your needs with our analyst

Please share your requirements with more details so our analyst can check if they can solve your problem(s)