Table of Contents

Overview

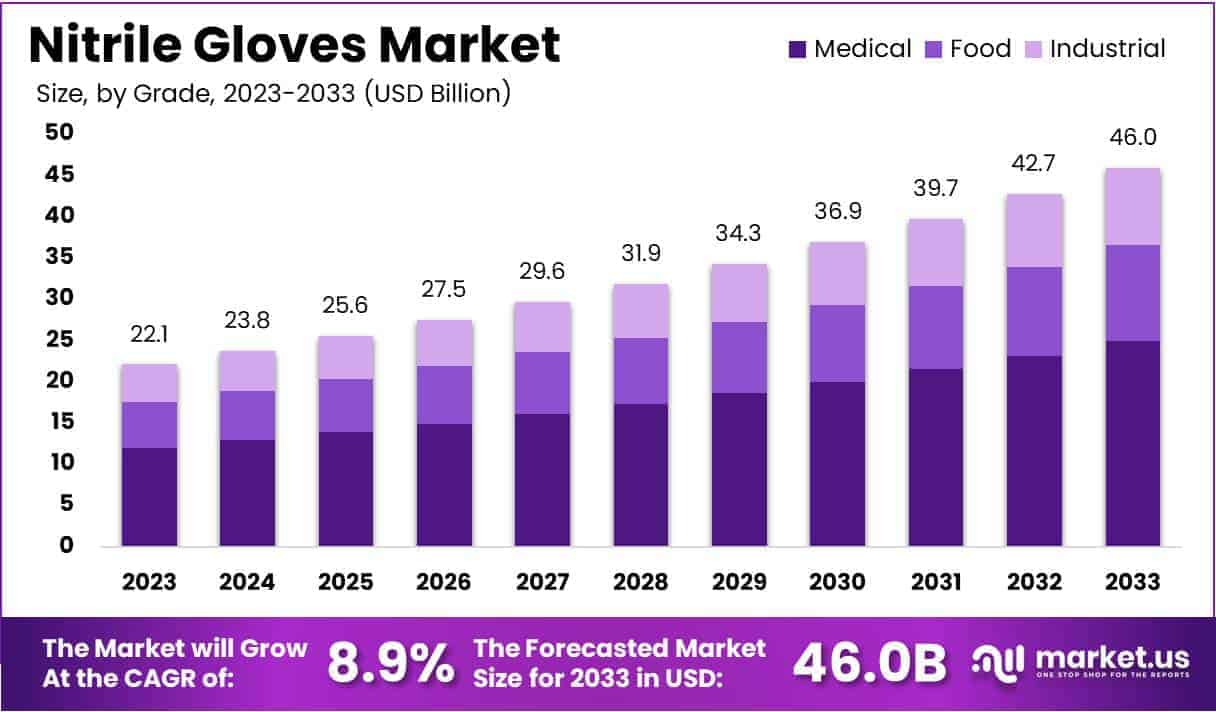

New York, NY – July 16, 2025: The Global Nitrile Gloves Market is on a firm growth path. Valued at USD 22.1 billion in 2023, it is projected to reach about USD 46 billion by 2033, reflecting a robust 8.9% CAGR from 2024 to 2033. This steady expansion highlights rising demand for safer, more versatile hand protection across healthcare and industrial domains. Continuous product innovation and wider acceptance of synthetic materials are positioning nitrile gloves as the preferred option over traditional latex, driving sustained revenue gains for manufacturers and distributors worldwide.

The COVID‑19 pandemic renewed global awareness of hygiene and infection control, propelling nitrile glove consumption to new heights. Health bodies such as the World Health Organization stress routine glove use during patient care, testing, and emergency response. Their guidance keeps demand elevated, even as acute outbreaks fade. Hospitals, clinics, and first‑responder units now treat disposable gloves as indispensable stock items. This behavioural shift has spilled into non‑medical segments, where routine cleaning, retail handling, and travel services all rely on nitrile gloves to reassure staff and customers.

Government policies are reinforcing this momentum. Many countries classify gloves as strategic medical supplies and include them in national reserves for pandemic preparedness. Long‑term procurement contracts signed by public health agencies provide volume certainty, allowing manufacturers to expand capacity and invest in automation. At the same time, tax incentives and subsidies encourage local production, reducing reliance on imports and strengthening supply security. These coordinated measures help smooth demand fluctuations, giving the nitrile glove market a stable baseline even when day‑to‑day healthcare consumption moderates.

A decisive shift away from latex is another growth engine. Natural latex proteins can trigger allergic reactions among healthcare workers and patients, leading to stricter hospital purchasing policies. Occupational safety agencies in the United States, Europe, and Asia now recommend non‑latex alternatives whenever feasible. Nitrile, being synthetic, delivers comparable tactile sensitivity without allergen risk. It also resists punctures and many chemicals better than vinyl or polyethylene options. As knowledge about latex sensitivity spreads, nitrile’s safety profile continues to widen its adoption curve.

Beyond healthcare, stringent workplace rules sustain demand across industry. In automotive, electronics, chemical, and oil‑and‑gas plants, regulators cite nitrile gloves for superior resistance to oils, solvents, and micro‑tears, reducing injury downtime. Food authorities such as the U.S. FDA and European Food Safety Authority also approve nitrile for direct contact with meat, dairy, and produce, helping prevent cross‑contamination along modern processing lines. Veterinary and animal‑health guidelines mirror these standards, cementing nitrile as a multipurpose barrier that supports global hygiene and quality‑control objectives.

Key Takeaways

- In 2023, the nitrile gloves market earned USD 22.1 billion and is projected to reach USD 46 billion by 2033, growing at 8.9% CAGR.

- Disposable gloves led the product category in 2023, accounting for 63.6% of the market due to their wide use in medical and industrial settings.

- Powder-free nitrile gloves dominated the type segment with 67.9% market share, largely because they reduce skin irritation and are safer for medical use.

- Among the different grades, medical-grade gloves held the top position in 2023, contributing 54.2% to total market revenue due to hospital and clinical demand.

- Micro-roughened gloves topped the texture segment with 47.5% share, preferred for better grip and handling during sensitive procedures and industrial tasks.

- The medical & healthcare sector led all end-users in 2023, securing a 42.9% market share driven by rising hygiene and safety standards.

- North America was the leading region in 2023, capturing 40.1% market share, thanks to strong healthcare infrastructure and safety regulation enforcement.

Segmentation Analysis

Product Analysis

Disposable nitrile gloves dominated 2023, holding 63.6% of market share. Growing infection‑control awareness in hospitals and food outlets lifted demand. Single‑use gloves cut cross‑contamination, so they are vital where hygiene is critical. COVID‑19 further boosted medical consumption. Modern manufacturing has lowered cost and raised supply. Convenience and clean handling will keep this segment strong in high‑risk settings.

Type Analysis

Powder‑free nitrile gloves captured 67.9% of sales in 2023. Users prefer them because powdered varieties may cause allergies. The FDA and other regulators now limit powdered gloves in healthcare. Powder‑free options offer equal protection without residue. They serve hospitals, food processors, and many industrial lines. Stricter hygiene rules reinforce adoption. Demand for safe, low‑allergen gloves drives rapid growth.

Grade Analysis

Medical‑grade nitrile gloves delivered 54.2% of revenue in 2023. Clinics rely on them for robust barriers against infection. These gloves resist punctures and stand up to tough procedures. Rising surgery volumes and disease outbreaks fuel use. Infection‑control mandates amplify uptake. With patient safety in focus, the segment keeps gaining ground. Medical‑grade gloves remain indispensable in care settings.

Texture Analysis

Micro‑roughened nitrile gloves earned 47.5% of revenues in 2023. Their fine texture improves grip and tactile feel. The surface holds firm in wet or oily conditions, reducing slips. Healthcare, labs, and food prep favor this precision. Ergonomic benefits add to attraction. By blending protection with control, these gloves have secured a strong niche.

End‑Use Analysis

Healthcare led end‑use demand in 2023 at 42.9%. Hospitals, clinics, and labs required more protective gear. The pandemic sharpened focus on infection barriers. Nitrile gloves shield staff from fluids, pathogens, and chemicals. Expanding healthcare infrastructure and higher patient loads extend demand. Regulators push stricter safety standards. Continued growth is likely as providers prioritize compliance and safety.

By Product

- Durable

- Disposable

By Type

- Powdered

- Powder-free

By Grade

- Medical

- Food

- Industrial

By Texture

- Micro-roughened

- Smooth

- Aggressively Textured

By End-Use

- Automotive

- Medical & Healthcare

- Examination

- Surgical

- Oil & Gas

- Metal & Machinery

- Cleanroom

- Pharmaceutical

- Food & Beverage

- Chemical & Petrochemical

- Others

Regional Analysis

North America holds the largest share in the nitrile gloves market, accounting for 40.1% of total revenue. This dominance is fueled by strict infection control measures and continued emphasis on PPE after the COVID-19 pandemic. Nitrile gloves are favored for their chemical resistance and durability over latex alternatives. Regulatory initiatives have supported their widespread use. In December 2023, Medline Industries, Inc. invested USD 300 million in strengthening the U.S. healthcare supply chain, ensuring reliable glove availability. Growth in healthcare facilities and telehealth further boosts market expansion.

Asia Pacific is expected to witness the fastest CAGR during the forecast period. The surge is driven by rising healthcare spending and growing focus on infection prevention across the region. Countries such as India, China, and Japan are leading this growth due to expanding healthcare infrastructure. Ansell Ltd. is investing USD 80 million in a new production facility in Tamil Nadu, India, set to be completed in 2024. This plant will manufacture various gloves, including surgical types. Increasing awareness of hygiene and safety is set to accelerate regional demand.

Key Players Analysis

Leading manufacturers of nitrile gloves are accelerating product innovation to cement their competitive edge. They roll out new glove lines with improved tensile strength, better tactile feel, and enhanced chemical resistance. At the same time, they commit heavy capital to enlarge production capacity so global orders can be filled without delay. Advanced automation, real‑time quality monitoring, and data‑driven maintenance lift plant efficiency while keeping defect rates low. These steps help suppliers align output with surging healthcare and industrial demand worldwide needs.

Market leaders also shore up distribution by partnering with regional wholesalers and logistics firms. These alliances shorten lead times, cut freight costs, and secure priority access to end‑users during demand spikes. Sustainability ranks high on the agenda. Firms pilot bio‑based polymers, invest in energy‑efficient curing ovens, and install closed‑loop water systems to shrink waste. They underscore these gains in ESG reports to win hospital tenders. Finally, players direct aggressive go‑to‑market campaigns toward Asia, Latin America, and Africa, where healthcare budgets are rising fast.

- Unigloves (UK) Limited

- Unigloves

- Supermax Corporation Berhad

- Superior Gloves

- MCR Safety

- Kossan Rubber Industries Bhd

- Ansell Limited

- Ammex Corporation

- Adenna LLC

Emerging Trends

Local Manufacturing Expansion

More countries are now making nitrile gloves locally. The shift started during the COVID-19 pandemic, which caused global supply chain disruptions. Companies want to avoid future shortages by producing gloves closer to where they’re used. Nations like the U.S. and Canada are opening new factories. Local manufacturing reduces dependence on imports and shortens delivery times. It also creates jobs and strengthens domestic industries. This trend helps ensure steady glove supply, especially in emergencies. It’s a key step in building self-reliant healthcare systems.

Safer and More Comfortable Formulations

Glove makers are focusing on comfort and skin safety. Some nitrile gloves now avoid harsh chemicals that cause irritation. This is good news for people who wear gloves for long hours. New formulations are gentler on skin and offer better breathability. Some gloves even include antimicrobial features to reduce germs. This makes them useful in medical and food-handling environments. These improved designs help reduce hand fatigue and allergic reactions. As user comfort becomes a priority, safer glove materials are becoming the new standard.

Increased Demand in Cleanroom Settings

Cleanrooms require gloves that don’t shed particles or dust. Nitrile gloves used in these areas must meet strict purity standards. Industries like electronics, biotechnology, and pharmaceuticals are growing fast. This growth is driving higher demand for high-purity gloves. These gloves help prevent contamination during sensitive processes. Even a small amount of debris can ruin products or experiments. Manufacturers are now producing more specialized gloves for these settings. As cleanroom technology evolves, so will the need for ultra-clean nitrile gloves.

Sustainability Policies Driving Change

Governments and industries are pushing for sustainable practices. Many now require products that produce less waste. This is influencing buyers to choose eco-friendly nitrile gloves. Some hospitals are using thinner gloves that reduce material use. Others are trying out biodegradable or even reusable gloves. Sustainability policies are shaping how companies select their supplies. They are also guiding manufacturers to rethink glove designs. This trend is about doing more with less—less waste, fewer resources, and more responsible use. It’s a strong force in shaping the future of the glove market.

Use Cases

Healthcare and Emergency Services

Nitrile gloves are essential in hospitals, clinics, and emergency settings. Doctors, nurses, and paramedics use them while treating patients or handling medical tools. These gloves create a protective barrier against bacteria, viruses, and chemicals. Unlike latex, nitrile gloves are safer for people with allergies. They are used during surgeries, routine exams, and when working with hazardous materials. Their durability and chemical resistance make them ideal for long medical shifts. First responders also depend on them in emergency scenes. Overall, nitrile gloves play a big role in protecting both patients and healthcare professionals.

Electronics and Cleanroom Manufacturing

In cleanroom settings like semiconductor plants or electronics factories, even tiny particles can ruin products. Nitrile gloves are used to maintain strict hygiene levels in these areas. They prevent contamination from sweat, skin oils, or dust. Workers use them while assembling sensitive parts like microchips, batteries, or circuits. These gloves are made with low particle release and meet cleanroom standards. Nitrile is also anti-static, which is crucial in electronic manufacturing. By wearing them, workers ensure product quality and protect delicate components from damage. Cleanroom gloves are often powder-free and specially tested.

Beauty and Personal Care

Nitrile gloves are popular in salons and beauty studios. Hairdressers, nail technicians, and tattoo artists wear them for hygiene and safety. These gloves protect hands from dyes, hair treatments, and other strong chemicals. They also keep clients safe from cross-contamination. Nitrile gloves are comfortable, tear-resistant, and don’t cause allergic reactions. Tattoo artists use them for long sessions due to their durability. Nail experts wear them while applying acrylics, gels, or polish removers. In beauty care, appearance and cleanliness matter, and these gloves help maintain both. They are now a standard tool in the beauty industry.

Home Use and DIY Projects

People use nitrile gloves at home for cleaning, painting, and small repairs. They help protect the skin from bleach, detergents, paint, and glue. These gloves are easy to wear and remove. Unlike latex, they don’t cause skin allergies and are more resistant to tears. Whether you’re fixing a leaky tap, scrubbing a bathroom, or working on a craft, nitrile gloves offer safe hand protection. Many homeowners keep a box in their toolkit or kitchen drawer. They are a simple way to stay safe during household chores or do-it-yourself projects.

Conclusion

In conclusion, the nitrile gloves market is growing steadily due to rising awareness about safety and hygiene across healthcare, industrial, and consumer sectors. These gloves are now seen as a reliable, allergy-free alternative to latex, with better protection against chemicals and punctures. Government support, local manufacturing, and product innovations are helping meet global demand. Nitrile gloves are being used in hospitals, cleanrooms, beauty salons, and even in households. As comfort, sustainability, and supply chain resilience become more important, the market is set to evolve further. With strong usage across many areas, nitrile gloves will remain an essential part of modern safety practices.