Table of Contents

Overview

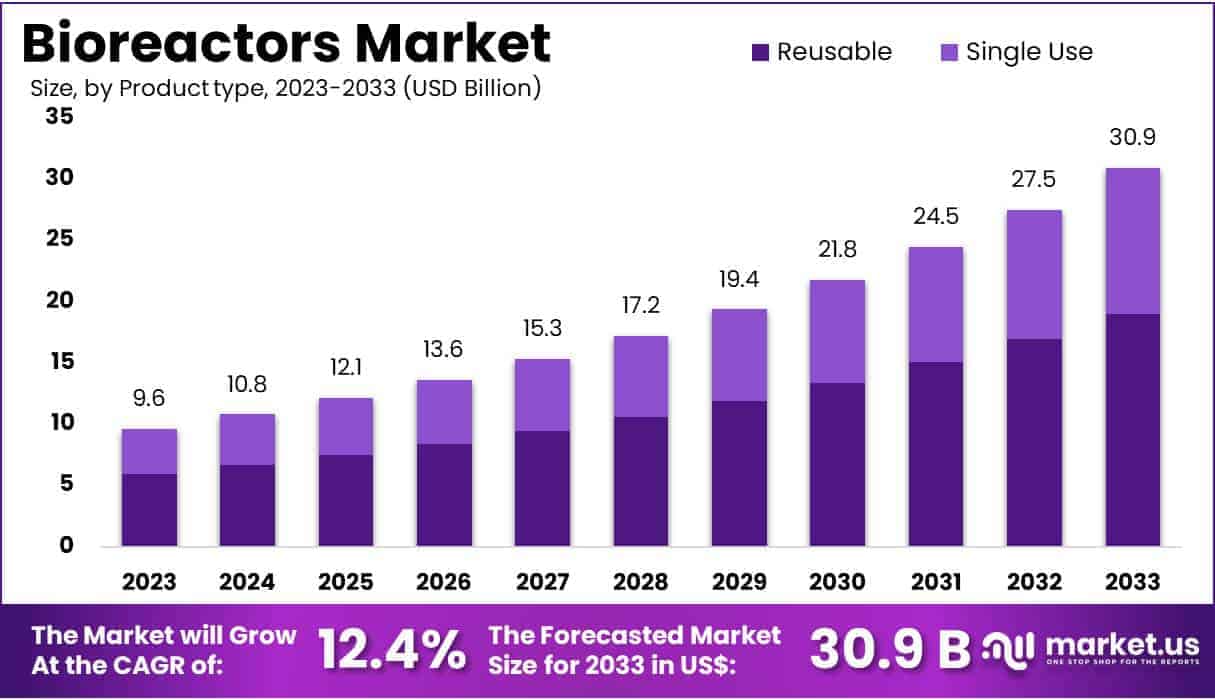

New York, NY – July 18, 2025: The Global Bioreactors Market is expected to increase from US$ 9.6 billion in 2023 to US$ 30.9 billion by 2033, growing at a CAGR of 12.4% between 2024 and 2033. A key driver of this growth is the rising demand for biopharmaceuticals, including vaccines, monoclonal antibodies, and gene-based therapies. Organizations such as the World Health Organization (WHO) are supporting broader access to these treatments. This has created a need for scalable and reliable bioreactor systems to meet high production standards and support global healthcare goals.

Technology is transforming how bioreactors are used in manufacturing. Today’s bioreactors come equipped with automated controls and smart sensors that improve production speed and quality. These innovations allow for precise process monitoring and better compliance with safety standards. Government policies are increasingly supporting automation in life sciences manufacturing. As a result, many biopharma labs and production facilities are upgrading to next-generation systems that offer higher efficiency and lower risk of contamination.

The growth of personalized medicine is also boosting the demand for advanced bioreactors. Cell and gene therapies, which are designed to match a patient’s unique biology, require very specific production conditions. Bioreactors provide a controlled environment for growing and managing these sensitive therapies. Public health programs and research grants are increasingly backing this shift toward customized treatment. This is helping drive the integration of bioreactor systems into cutting-edge clinical and research settings.

Single-use bioreactors are gaining strong traction across the industry. These systems are simpler to install, easier to clean, and reduce the chances of cross-contamination. They are especially useful in small-scale labs or during early-stage drug development. In addition, single-use models consume less energy and water, making them more sustainable than traditional stainless-steel systems. Many health authorities view this shift as part of a broader move toward greener, more agile biomanufacturing.

Emerging markets are becoming a key focus for bioreactor expansion. Countries in Asia, Africa, and Latin America are investing in local production of biologics and vaccines. Governments are supporting this growth through funding programs, tax incentives, and infrastructure development such as biotech hubs. These regional initiatives are helping smaller firms adopt modern bioreactor technology and build domestic capacity. As a result, the global bioreactors market is seeing balanced growth across both developed and developing economies.

Key Takeaways

- In 2023, the global bioreactors market generated US$ 6 billion and is expected to grow to US$ 30.9 billion by 2033.

- This market is growing at a strong CAGR of 12.4%, driven by increasing demand for biopharmaceuticals and advanced cell culture technologies.

- Bioreactors are categorized into single-use and reusable types, with reusable bioreactors dominating 2023, capturing 61.5% of the total share.

- When segmented by cell type, mammalian cells led the market in 2023, holding a notable 47.9% revenue share due to their compatibility with human therapeutics.

- Among molecule types, vaccines emerged as the top segment, accounting for the largest market share of 42.6% during 2023.

- In terms of usage, the preclinical and clinical production segment led the market, contributing 50.3% of the overall revenue in 2023.

- End-use data shows biopharmaceutical manufacturers as the top contributors, holding a 53.1% market share, driven by large-scale biologics production.

- North America emerged as the leading regional market, securing 38.4% share in 2023, supported by high R&D investment and strong healthcare infrastructure.

Segmentation Analysis

Product Type Analysis

In 2023, reusable bioreactors dominated the market with a 61.5% share. This was mainly due to the growing need for cost-efficient and sustainable production methods. Reusable systems help manufacturers cut costs and reduce waste over time. Advances in cleaning and sterilization technologies have made these systems more reliable. Supportive regulations promoting eco-friendly practices further boost their use. As the focus shifts toward greener manufacturing and efficient operations, reusable bioreactors are expected to stay the preferred option in biopharmaceutical production.

Cell Analysis

Mammalian cells led the market in 2023, securing a 47.9% share. Their dominance comes from their ability to produce complex biologics such as monoclonal antibodies. These cells enable crucial post-translational modifications, making them ideal for modern therapies. With rising demand for precision treatments, mammalian cells are increasingly essential in drug development. Technological improvements in cell culture are enhancing productivity and scalability. The segment is also expanding with the development of advanced cell lines. This positions mammalian cells as a vital part of biomanufacturing.

Molecule Analysis

In 2023, vaccines topped the molecule segment, capturing a 42.6% revenue share. This surge was driven by the global response to infectious disease outbreaks. Vaccines require rapid, scalable production, making bioreactors essential. New advancements in DNA technology and vaccine delivery are improving both speed and effectiveness. The rise of mRNA and vector-based vaccines is also accelerating innovation. Public health initiatives continue to focus on broader immunization efforts. This ensures that the vaccine segment will remain a cornerstone of modern biopharmaceutical manufacturing.

Usage Analysis

The preclinical and clinical segment contributed 50.3% of market revenue in 2023. This growth reflects the increasing number of drugs entering early trial phases. Scalable bioreactor systems are crucial for small-batch testing and process optimization. Regulatory agencies now emphasize strong data from these early stages, pushing demand for reliable bioprocessing tools. Higher investment in biotechnology R&D is also expanding this segment. As companies look to speed up drug development timelines, the need for effective systems in preclinical and clinical use will continue rising.

End-Use Analysis

In 2023, biopharmaceutical manufacturers held a 53.1% market share, leading the end-use segment. This growth is due to rising demand for biologics and advanced therapies. Manufacturers are upgrading to modern bioprocessing systems to meet the complex needs of these treatments. The increase in chronic diseases is also pushing demand for effective solutions. Collaborations with research institutions are fostering innovation. Additionally, contract manufacturing is helping companies scale efficiently. These factors highlight the key role manufacturers play in shaping the future of bioreactor applications in healthcare.

By Product Type

- Single Use

- Reusable

By Cell

- Mammalian Cells

- Yeast Cells

- Bacterial Cells

- Others

By Molecule

- Vaccines

- Monoclonal Antibodies

- Recombinant Proteins

- Gene Therapy

- Stem Cells

- Others

By Usage

- Preclinical & Clinical

- Developmental

- Commercial Production

By End-Use

- Research & Development Organizations

- Biopharmaceutical Manufacturers

- Contract Manufacturing Organizations

Regional Analysis

North America Bioreactors Market Overview

North America led the global bioreactors market with a 38.4% revenue share. This growth is driven by rising demand for cell and gene therapies, fueled by the increase in chronic diseases and personalized medicine needs. Advancements in bioprocessing, like the compact bioreactor from Washington State University, have boosted efficiency by enabling T cell production 30% faster than older systems. Continued investment in R&D and the push for scalable biologics manufacturing are expanding bioreactor applications across the region, making North America a key market driver.

Asia Pacific Bioreactors Market Growth Outlook

The Asia Pacific bioreactors market is projected to grow at the highest CAGR during the forecast period. Rising healthcare needs and growing access to advanced treatments are driving biopharmaceutical production. Countries like China and India are increasing investments in biotechnology. In April 2023, Cytiva launched new X-platform bioreactors aimed at improving process efficiency. This, along with better healthcare infrastructure and a stronger focus on vaccine production, is boosting demand for bioreactor technologies across the region, positioning Asia Pacific as a fast-emerging market.

Key Players Analysis

Leading companies in the bioreactors market are prioritizing innovation to boost their competitive edge. They are making strong investments in research and development to create advanced solutions such as single-use and continuous-flow bioreactors. These technologies offer better scalability, improved process control, and lower production costs. To stay ahead of market trends, many firms are partnering with biotech companies and research institutes. These collaborations help them adopt the latest technologies quickly and meet the growing need for biologics like vaccines and cell therapies.

Alongside innovation, major players are working to widen their global reach. They are forming strategic alliances, acquiring firms, and building distribution networks, especially in fast-growing biomanufacturing markets. Many companies are also strengthening customer support and training services. This helps clients effectively use and maintain bioreactor systems. Strong service offerings build long-term relationships and encourage repeat business. These efforts not only increase customer satisfaction but also drive steady growth and market expansion in a highly competitive environment.

Emerging Trends

Wider Use of Single-Use Bioreactors

Single-use bioreactors are becoming a go-to solution in the biopharmaceutical sector. These systems use disposable plastic components, which eliminate the need for time-consuming cleaning and sterilization. As a result, companies can speed up their workflows and reduce contamination risks. They’re also more water- and energy-efficient, making them better for the environment. Their flexibility makes them ideal for producing multiple products in small batches. Many firms prefer them for clinical trials and early manufacturing because they are easy to install and maintain. This shift is helping businesses become more responsive and cost-effective.

Rise of Continuous Bioprocessing

Biopharma companies are moving away from traditional batch processing toward continuous production. This approach keeps the process running non-stop, leading to a more consistent product output. It improves the efficiency of equipment use, reduces waste, and lowers downtime. Continuous bioprocessing also helps meet the growing demand for biologics more effectively. It’s being used in both upstream and downstream operations to enhance productivity. With faster turnaround times and improved product quality, continuous systems are becoming a key part of modern manufacturing strategies.

Smart Bioreactors Powered by Automation and AI

Today’s bioreactors are equipped with smart technologies like automation and artificial intelligence. These advanced systems monitor and adjust critical parameters—such as pH, oxygen levels, and temperature—in real time. They respond quickly to any changes, keeping the process stable and efficient. AI tools also help predict maintenance needs and prevent errors. This reduces downtime and boosts overall productivity. Smart bioreactors support remote monitoring, making it easier to manage production across multiple sites. As digital solutions evolve, these intelligent systems are transforming the future of biomanufacturing.

Push for Sustainable Bioreactor Technologies

Sustainability is becoming a major focus in the bioreactor industry. Companies are developing energy-efficient systems that reduce water usage and cut plastic waste. Reusable bioreactors are seeing renewed interest, especially for large-scale or long-term use. Eco-friendly materials and smarter designs help reduce environmental impact while maintaining high performance. Regulations are also encouraging greener practices. Advanced monitoring tools now track energy and resource consumption to improve efficiency. As industries aim to lower their carbon footprint, sustainable bioreactor technologies are playing a critical role in achieving those goals.

Use Cases

Vaccine and Antibody Production

Bioreactors play a big role in making vaccines and monoclonal antibodies. They are used to grow mammalian cells, which are key in producing these medicines. During health emergencies like pandemics, bioreactors help companies quickly increase vaccine production. Their ability to maintain sterile and controlled environments makes them ideal for large-scale production. These systems ensure the cells grow properly and produce the needed proteins. Without bioreactors, it would be very difficult to meet the urgent global demand for vaccines. Their use continues to rise as more biologic drugs are developed. This makes them essential in the pharmaceutical and biotech industries.

Cell and Gene Therapy Manufacturing

Bioreactors are crucial in making advanced treatments like CAR-T cell therapy. In these therapies, cells are taken from a patient, modified, and then returned to the body. This process needs a clean and highly controlled environment. Bioreactors offer just that. They help keep the cells alive and growing in the right way. These systems allow for precise control over temperature, oxygen, and pH. That’s important because even small changes can affect cell health. As cell and gene therapies grow in popularity, the use of bioreactors in this space is also increasing. They make these life-saving treatments more reliable and scalable.

Cultivated (Lab-Grown) Meat

Bioreactors are now used in food technology to grow real meat without harming animals. In this process, animal cells are grown inside bioreactors. These systems mimic the body’s natural conditions, helping the cells grow into meat. This kind of meat is called cultivated or lab-grown meat. It’s seen as a future-friendly option that uses fewer resources and causes less harm to the planet. Companies working on sustainable food solutions use bioreactors to create cleaner meat alternatives. As consumers look for ethical food choices, demand for this kind of meat is increasing. Bioreactors make this new way of producing meat possible.

Industrial Enzyme Production

Enzymes are used in many products like detergents, food, and textiles. Bioreactors help produce these enzymes by growing specific microbes. These microbes release enzymes that can be harvested and used in various industries. Bioreactors allow for high-volume and cost-efficient enzyme production. The environment inside the reactor is controlled, which leads to better quality enzymes. For companies, this means better results and fewer waste materials. Whether it’s breaking down stains in laundry or improving food processing, these enzymes are everywhere. Bioreactors make it easier to meet large-scale industrial needs while keeping the process clean and efficient.

Conclusion

The bioreactors market is growing rapidly due to the rising demand for advanced medicines and sustainable production methods. These systems are becoming essential in making vaccines, antibodies, cell therapies, and even lab-grown meat. As technology evolves, smart and single-use bioreactors are making processes faster, cleaner, and more efficient. Companies across the world are investing in modern bioreactor systems to meet global health goals and improve drug development. At the same time, sustainability and automation are shaping the future of biomanufacturing. With strong support from both governments and the healthcare sector, bioreactors are expected to play a bigger role in research, clinical use, and commercial production across industries.

Discuss your needs with our analyst

Please share your requirements with more details so our analyst can check if they can solve your problem(s)