Table of Contents

Introduction

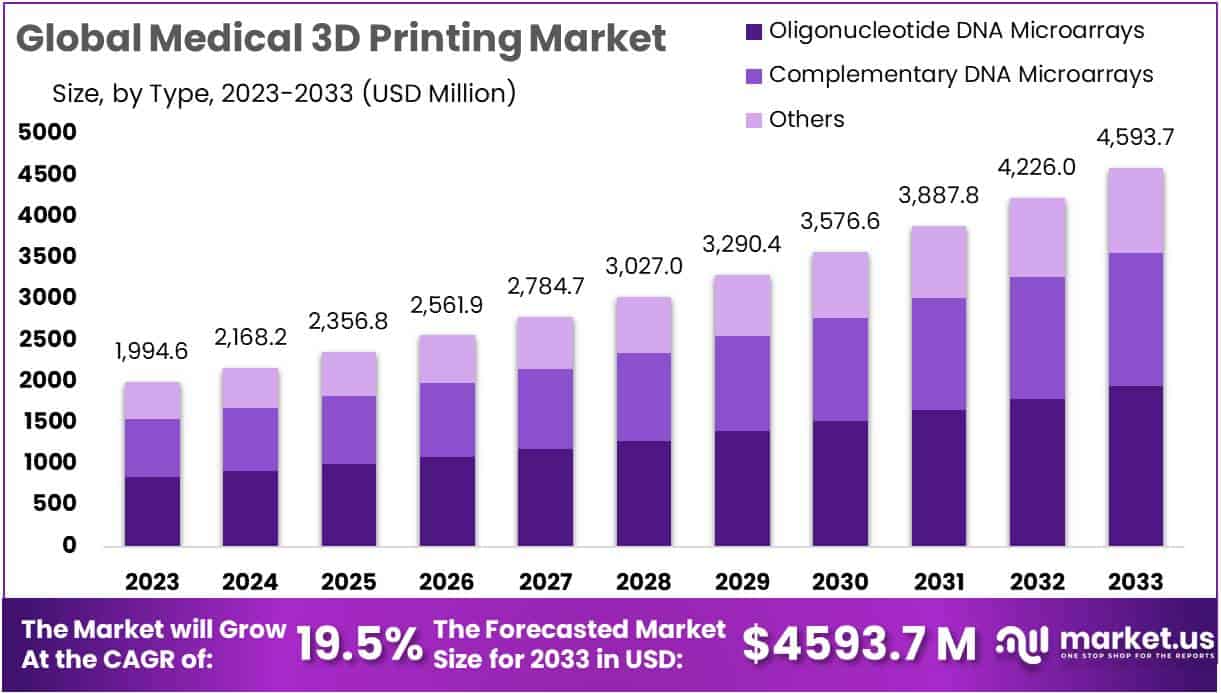

The Global Medical 3d Printing Market is projected to reach USD 4,593.7 million by 2033, up from USD 1,994.6 million in 2023. This growth is anticipated at a robust CAGR of 19.5% during the forecast period from 2024 to 2033. The expansion is driven by a rising demand for patient-specific medical solutions, continued innovation in printing technologies, and increased integration across various medical applications. The market is analyzed by components (systems, materials, services), technologies (such as droplet deposition and photopolymerization), applications (like implants and tissue engineering), and end-users including hospitals and academic institutions.

A major factor fueling this market is the growing preference for personalized medical devices. 3D printing allows for the precise design of patient-specific implants and prosthetics, improving comfort and clinical outcomes. This trend is especially relevant in orthopedics and dentistry, where tailored devices are essential. Additionally, biocompatible materials and advanced software have enabled the production of complex geometries that were previously difficult to manufacture using conventional techniques.

Technological advancements in 3D printing hardware and software have significantly improved the accuracy, speed, and accessibility of the technology. These innovations support the creation of intricate structures such as scaffolds for tissue engineering and regenerative medicine. Moreover, the use of 3D-printed models in pre-surgical planning and medical education has increased. These models provide better visualization of patient anatomy, helping surgeons plan complex procedures and offering students hands-on learning experiences.

The establishment of dedicated 3D printing centers and increased investment by health-tech companies are further accelerating market growth. New bioprinting facilities aim to develop functional human tissues and organs, enhancing both diagnostics and therapeutic applications. Additionally, regional expansions and strategic partnerships are enabling more widespread adoption across hospitals and research institutions. This, in turn, is improving access to advanced medical solutions, especially in developing healthcare markets.

Government initiatives and public-private partnerships have played a supportive role in promoting this technology. Funding for R&D, infrastructure development, and regulatory support are facilitating the wider implementation of 3D printing in the healthcare sector. These efforts help address challenges such as high production costs and limited access, making the technology more viable for routine clinical use. As a result, the medical 3D printing market is expected to see sustained growth, driven by its ability to deliver high-quality, cost-effective, and personalized healthcare solutions.

Key Takeaways

- The market is projected to reach USD 4,593.7 million by 2033, expanding at a strong CAGR of 19.5% from 2024 onward.

- In 2023, the droplet deposition segment led the technology landscape, capturing over 29.5% of the overall market share.

- External wearable devices emerged as the leading application in 2023, accounting for more than 39.2% of the total market share.

- Hospitals dominated the market in 2023, holding a significant 46.3% share, driven by increasing adoption of bioprinting-based medical solutions.

- The rise in bioprinting innovations has led to projected global spending of $23 billion by 2022, supporting robust industry expansion.

- Regulatory complexities and ethical concerns continue to hamper development, causing delays and driving up associated costs in the product lifecycle.

- The integration of artificial intelligence and machine learning is enabling more streamlined and efficient bioprinting production processes across the sector.

- North America led the global market in 2023 with a 44.1% share, while Europe and Asia-Pacific are showcasing strong future growth prospects.

Emerging Trends

- Automation in 3D Printing Workflows: Automation is becoming a key driver in medical 3D printing. It helps reduce manual work and speeds up the printing process. Automated systems now handle tasks like design optimization, material handling, and quality control. These systems improve workflow efficiency and ensure consistent print quality. As a result, production times are getting shorter. This trend also reduces human error, which is critical in medical applications. Automation allows healthcare providers to deliver custom-made solutions more quickly. It also supports scalability in manufacturing. Overall, the use of automation is transforming 3D printing into a faster and more reliable tool for the medical sector.

- Expansion of Applications: Medical 3D printing is expanding beyond its traditional areas. Earlier, it was mostly used in orthopedics and cranio-maxillofacial surgery. Today, its use has reached cardiology. Patient-specific heart models are now being printed to support diagnosis and surgical planning. These models help doctors better understand complex cardiac conditions. They also improve the accuracy of procedures by offering detailed anatomical insights. With better visuals and planning, patient outcomes are expected to improve. The growing application of 3D printing across new medical fields shows its versatility. This trend highlights the increasing trust in 3D printing as a reliable clinical tool.

- Cloud Integration: Cloud-based platforms are changing how 3D printing is used in healthcare. These platforms allow medical teams to store and share 3D models and patient data securely. Doctors and engineers can now collaborate remotely in real time. This improves planning and consultation, especially in urgent or complex cases. Cloud integration also ensures that all teams have access to the latest version of a model. It reduces errors and boosts coordination. This trend makes 3D printing more accessible, even in facilities without in-house experts. As cloud systems grow, they will continue to support the wider adoption of 3D printing in medicine.

- Advancements in Bioprinting: Bioprinting is making major progress in healthcare research. Scientists are working on printing tissues and organs using living cells. The goal is to create functional, transplantable body parts. Though still in early stages, some successes have been seen in printing skin, cartilage, and small blood vessels. These developments could solve the shortage of organ donors in the future. Bioprinting also allows for the creation of personalized tissue models for drug testing. This can reduce the need for animal testing. As research continues, bioprinting holds strong promise for regenerative medicine and long-term medical breakthroughs.

- Point-of-Care Manufacturing: Point-of-care 3D printing is gaining attention in hospitals and clinics. It refers to setting up printing labs inside healthcare facilities. This enables the quick production of custom medical devices, often within hours. Items like surgical guides, prosthetics, and implants can be made on demand. This approach cuts down lead time and logistics issues. It also ensures a better fit for the patient, improving comfort and effectiveness. Point-of-care manufacturing empowers clinicians to respond faster to patient needs. As the technology becomes more user-friendly, more healthcare providers are expected to adopt this in-house capability.

Use Cases

- Customized Implants and Prosthetics: Medical 3D printing makes it possible to create implants and prosthetics that fit each patient’s unique anatomy. This level of customization increases comfort and improves how the devices function. For example, prosthetic limbs made using 3D printing offer better movement and control. A notable use case is in hearing aids. More than 10 million 3D-printed hearing aids are used globally today. This shows how widely the technology has been adopted. 3D printing helps reduce production time and allows for design adjustments with ease. As a result, patients get solutions that are more precise and effective compared to traditional methods.

- Surgical Planning and Education: Surgeons now use 3D-printed anatomical models for pre-surgical planning. These models represent a patient’s actual anatomy. This helps surgeons understand complex cases better before entering the operating room. Studies show that using these models can reduce surgery times by around 12%. This improves overall efficiency and lowers risks. Medical students also benefit from this technology. They can study and practice on realistic models that mimic human organs and tissues. This provides hands-on learning without needing a real patient. As a result, both education and patient care see significant improvements.

- Production of Medical Devices and Instruments: 3D printing helps create medical tools that are tailored to specific needs. These include surgical instruments and custom-fit devices. Customization improves precision during operations and leads to better outcomes for patients. One important example was during the COVID-19 pandemic. Hospitals faced a severe shortage of personal protective equipment (PPE). 3D printers were used to quickly produce face shields, masks, and ventilator parts. This helped fill urgent supply gaps. The ability to make devices on demand has proven valuable in emergencies. It also opens the door to faster and more flexible healthcare solutions.

- Bioprinting Tissues and Organs: Bioprinting is a specialized form of 3D printing that uses living cells. It aims to create functional tissues and, eventually, whole organs. This field is still in its early stages, but progress is steady. Scientists have successfully printed small tissue samples like skin, cartilage, and liver tissue. In the future, this technology could solve the shortage of organ donors. It could also support personalized treatment plans in regenerative medicine. While large-scale clinical use is not yet possible, ongoing research continues to show promise. Bioprinting could transform how we treat injuries and chronic diseases.

Conclusion

In conclusion, the medical 3D printing market is growing steadily due to its ability to deliver patient-specific healthcare solutions. The technology is making a strong impact across various medical fields, including orthopedics, cardiology, and surgical planning. Its benefits, such as faster production, better customization, and improved clinical outcomes, are driving its adoption in hospitals and research institutions. Innovations like bioprinting, cloud integration, and point-of-care manufacturing are expanding the scope of its applications. Despite some challenges, such as cost and regulation, ongoing research and government support are helping the industry move forward. As a result, medical 3D printing is becoming a key part of the future of modern healthcare.

Discuss your needs with our analyst

Please share your requirements with more details so our analyst can check if they can solve your problem(s)