Table of Contents

Overview

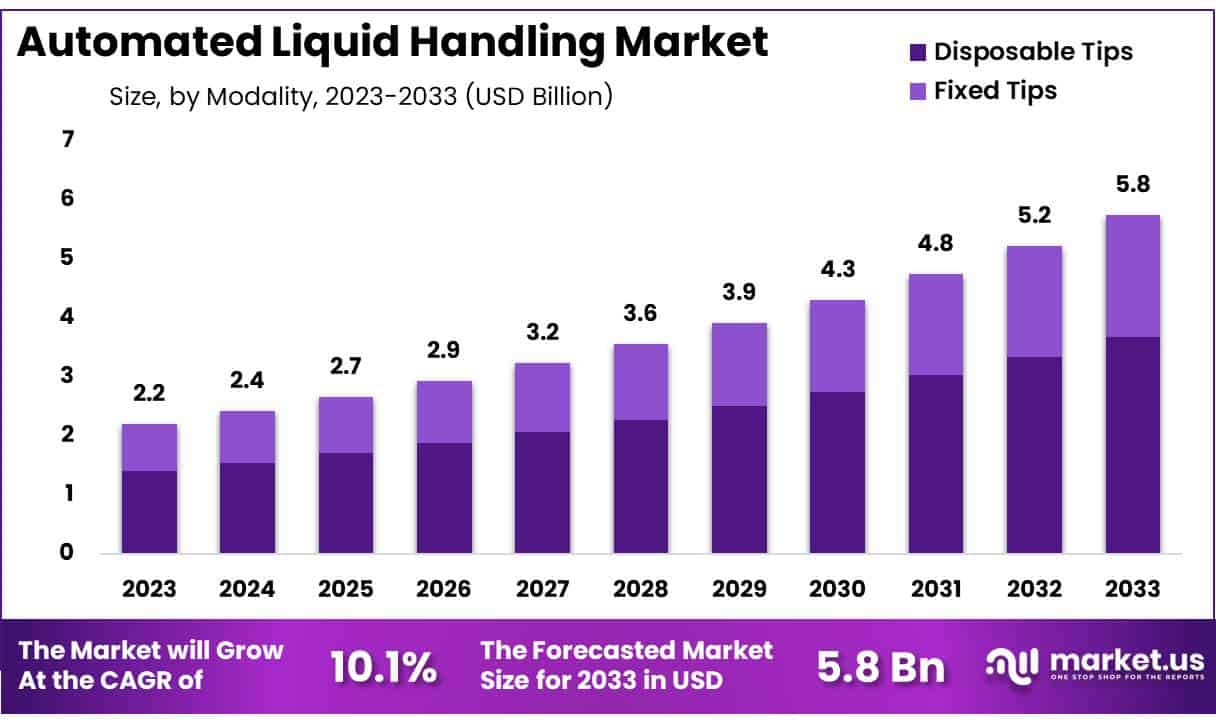

New York, NY – Jan 08, 2026 – Global Automated Liquid Handling Market size is expected to be worth around USD 5.8 billion by 2033 from USD 2.2 billion in 2023, growing at a CAGR of 10.1% during the forecast period 2024 to 2033.

Automated liquid handling systems are increasingly being adopted across research, diagnostics, and industrial laboratories due to their ability to improve accuracy, consistency, and operational efficiency. These systems are designed to automatically dispense, transfer, dilute, and mix liquid samples with a high degree of precision, reducing manual intervention and human error.

The basic formation of an automated liquid handling system typically includes robotic arms, pipetting modules, liquid reservoirs, disposable or fixed tips, control software, and integrated sensors. Robotic arms are used to move plates, tubes, or tips between different positions, while pipetting modules ensure accurate volume transfer across a wide range of applications. Advanced software platforms control workflows, allowing protocols to be standardized, stored, and repeated with minimal variation.

The adoption of automated liquid handling can be attributed to the growing demand for high-throughput screening, reproducibility, and compliance with quality standards. In pharmaceutical and biotechnology laboratories, these systems support drug discovery, genomics, proteomics, and sample preparation processes. In clinical and diagnostic settings, automated liquid handling contributes to faster turnaround times and improved reliability of test results.

Furthermore, automation is enabling laboratories to optimize resource utilization by reducing reagent waste and labor costs. As research complexity increases and sample volumes continue to rise, automated liquid handling is expected to play a critical role in supporting scalable and efficient laboratory operations.

Key Takeaways

- Market Size: The global automated liquid handling market is projected to reach approximately USD 5.8 billion by 2033, rising from an estimated USD 2.2 billion in 2023.

- Market Growth: Market expansion is anticipated at a compound annual growth rate (CAGR) of 10.1% over the forecast period from 2024 to 2033.

- Modality Analysis: In 2023, the disposable tips segment accounted for the largest market share at 63.8%, driven by rising demand for high-precision and contamination-free liquid handling across laboratory environments.

- Procedure Analysis: The serial dilution segment captured a notable share of 32.8%, supported by its essential application in drug discovery, microbiology, and analytical research workflows.

- Type Analysis: The standalone systems segment recorded strong growth, representing a revenue share of 55.1%, primarily due to their operational flexibility, cost efficiency, and user-friendly design.

- End-Use Analysis: Biotechnology and pharmaceutical companies emerged as the leading end-use segment, contributing 54.4% of total market revenue, reflecting increased automation adoption in research and development activities.

- Regional Analysis: North America led the global market in 2023, securing the highest revenue share of 40.1%, supported by advanced laboratory infrastructure and strong investment in life sciences research.

Regional Analysis

North America Leads the Automated Liquid Handling Market

North America accounted for the largest share of the automated liquid handling market, capturing 40.1% of total revenue. This leadership position can be attributed to the rising demand for precision, speed, and operational efficiency in laboratory workflows across pharmaceuticals, biotechnology, genomics, and clinical research. The accelerated need for high-throughput testing and large-scale sample processing, particularly following the COVID-19 pandemic, has further strengthened the adoption of automated liquid handling solutions.

A notable industry advancement was observed in November 2023, when SPT Labtech introduced Firefly for LDT, a solution aimed at improving liquid handling efficiency in laboratory-developed tests based on next-generation sequencing. This launch reflects the broader industry focus on workflow optimization, accuracy enhancement, and reproducibility in complex laboratory environments. Increased investments in research and development, coupled with continuous automation integration, have reinforced market growth across the region.

Asia Pacific Expected to Register the Fastest Growth

Asia Pacific is projected to witness the highest compound annual growth rate during the forecast period. This growth is driven by rapid technological advancements, expanding pharmaceutical and biotechnology research, and increasing investments in healthcare infrastructure. Countries such as China, India, and Japan are expected to lead regional expansion. Growing emphasis on high-throughput screening, precision medicine, and collaborative innovation is anticipated to significantly boost the adoption of automated liquid handling systems across the region.

Emerging Trends

- Integration of Artificial Intelligence (AI) and Machine Learning (ML): Automated Liquid Handling (ALH) systems are increasingly being enhanced with AI and ML capabilities to improve operational efficiency. These technologies support real-time workflow optimization, predictive maintenance, and data-driven decision-making, resulting in higher laboratory productivity and reduced downtime.

- Miniaturization and Microfluidics: Ongoing advancements in microfluidic technologies have enabled ALH systems to manage extremely low liquid volumes with high accuracy. This trend supports reduced reagent consumption and facilitates high-throughput applications, particularly in drug discovery and genomic research.

- Improved Contamination Control: Modern ALH platforms are adopting non-contact and low-carryover dispensing technologies to significantly reduce the risk of cross-contamination. This feature is critical for high-sensitivity applications such as single-cell analysis and next-generation sequencing workflows.

- Scalability and Operational Flexibility: ALH systems are being designed with modular and scalable architectures, allowing laboratories to adjust capacity based on evolving research requirements. This flexibility enables efficient transition from small-scale experiments to large-scale screening operations.

- Advanced Data Management and System Integration: Integration with Laboratory Information Management Systems (LIMS) has become a standard feature in ALH platforms. This integration ensures comprehensive data traceability, regulatory compliance, and enhanced analytical capabilities across laboratory workflows.

Key Use Cases

- Clinical Diagnostics: ALH systems are widely utilized in clinical laboratories for sample preparation, reagent dispensing, and assay configuration. Automation improves throughput, minimizes manual errors, and enhances the reliability and reproducibility of diagnostic testing.

- Drug Discovery and Development: In pharmaceutical research, ALH systems support high-throughput screening of large compound libraries. The precision and speed of automation contribute to faster identification of promising drug candidates and improved efficiency across development pipelines.

- Genomics and Proteomics: ALH platforms enable automated execution of complex workflows such as nucleic acid extraction, PCR setup, and sequencing library preparation. Automation ensures consistency, accuracy, and reproducibility in genomics and proteomics research.

- Biomanufacturing: Within biopharmaceutical manufacturing, ALH systems are applied to media preparation, cell culture processes, and quality control testing. Automation supports scalable production while maintaining process consistency and compliance with regulatory standards.

- Environmental Testing: Environmental laboratories employ ALH systems for automated preparation and analysis of water, soil, and air samples. This automation enhances analytical accuracy, improves throughput, and supports reliable environmental monitoring and compliance testing.

Frequently Asked Questions on Automated Liquid Handling

- Where is automated liquid handling commonly used?

Automated liquid handling is widely used in pharmaceutical research, clinical diagnostics, genomics, proteomics, and biotechnology laboratories. It supports applications such as sample preparation, reagent dispensing, assay development, and compound screening processes. - What are the key benefits of automated liquid handling systems?

The adoption of automated liquid handling systems enables improved reproducibility, enhanced throughput, reduced contamination risk, and lower labor dependency. These advantages contribute to operational efficiency and consistent data quality in regulated laboratory environments. - What types of automated liquid handling systems are available?

Automated liquid handling systems are available as standalone workstations, integrated robotic platforms, and modular systems. They may operate using pipette-based, dispenser-based, or acoustic-based technologies, depending on application requirements and precision needs. - What factors influence system selection?

System selection is influenced by throughput requirements, liquid volume range, accuracy standards, laboratory space, software compatibility, and budget constraints. End-use application complexity and regulatory compliance requirements also play a significant role in purchasing decisions. - What is driving the growth of the automated liquid handling market?

Market growth is driven by increasing demand for high-throughput screening, rising pharmaceutical research investments, expanding diagnostic testing volumes, and the need for laboratory automation to improve productivity and reduce operational variability across workflows. - Which end-user segments dominate the market?

Pharmaceutical and biotechnology companies represent the largest end-user segment, followed by academic research institutes and clinical laboratories. Contract research organizations are also contributing significantly due to increased outsourcing of drug discovery and testing activities. - What regional trends are observed in the market?

North America holds a leading market share due to strong research funding and advanced laboratory infrastructure. Europe follows closely, while Asia-Pacific is experiencing accelerated growth driven by expanding biotechnology sectors and healthcare investments.

Conclusion

The automated liquid handling market is positioned for sustained growth, supported by rising demand for accuracy, throughput, and reproducibility across laboratory environments. Increasing adoption in pharmaceutical, biotechnology, and clinical diagnostics laboratories has reinforced its role as a core component of modern research infrastructure.

Advancements in software integration, AI-enabled optimization, and microfluidic precision are further enhancing system capabilities. Strong market performance in North America and rapid expansion in Asia Pacific highlight favorable regional dynamics. As laboratory workloads grow in complexity and scale, automated liquid handling systems are expected to remain essential for efficient, compliant, and scalable laboratory operations.

Discuss your needs with our analyst

Please share your requirements with more details so our analyst can check if they can solve your problem(s)