Table of Contents

Overview

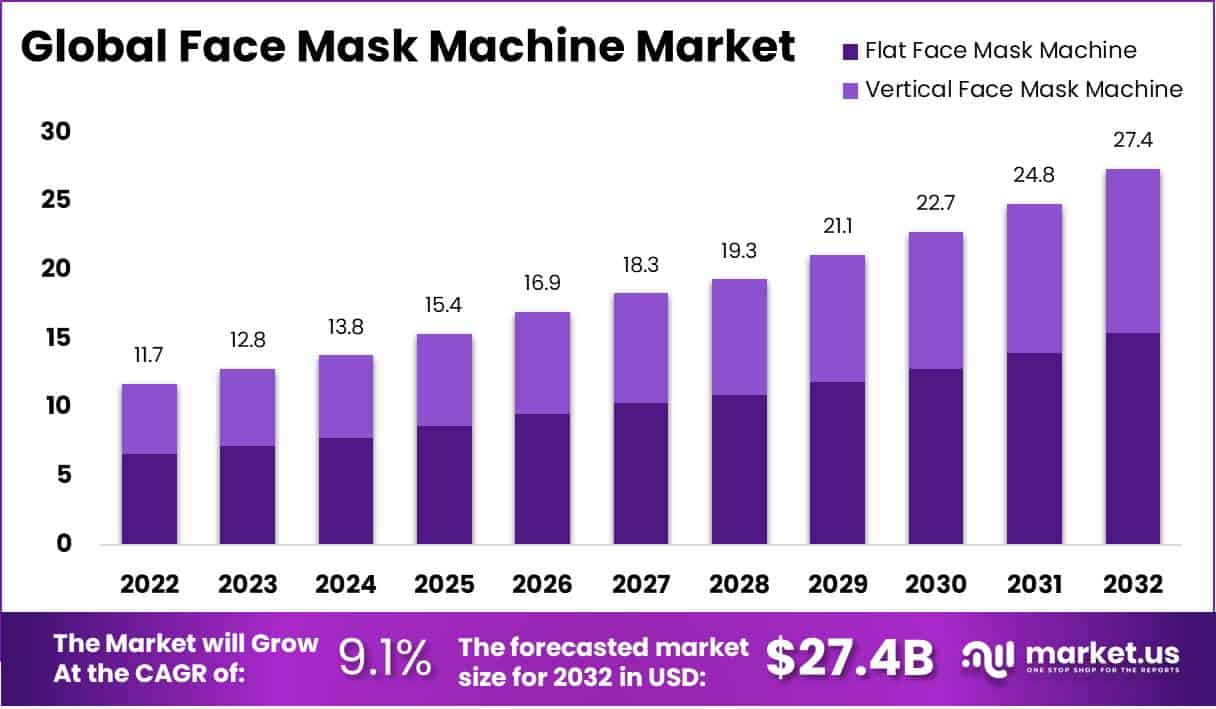

New York, NY – June 18, 2025: The Face Mask Machine Market is projected to reach USD 27.4 billion by 2032, up from USD 11.7 billion in 2022, reflecting a CAGR of 9.1% from 2023 to 2032. This growth is driven by lasting public health concerns, technological advances, and regulatory support. According to the World Health Organization (WHO), global demand for masks surged during the COVID-19 outbreak. In March 2020 alone, approximately 89 million medical masks were needed monthly, with prices increasing up to sixfold. In response, manufacturers rapidly expanded their face mask production capacity, triggering demand for automated mask machines.

Government strategies for enhancing supply chain resilience have further boosted the sector. Studies from WHO and CDC during the pandemic exposed the vulnerability of global PPE supply networks, particularly the over-reliance on imports and the absence of real-time inventory tracking. Consequently, several countries have started supporting localized production. This shift involves the installation of face mask machines in national manufacturing units to improve self-sufficiency and emergency preparedness.

In response to environmental challenges, sustainability is becoming a central focus. WHO reports estimated that plastic waste from disposable masks ran into hundreds of tonnes per week in 2020. As a solution, healthcare systems and governments are moving toward reusable respirators. Technologies such as elastomeric half-mask respirators (EHMRs), evaluated and promoted by the CDC, are now being integrated into practice. This transition has created a new demand for versatile mask machines that can produce both reusable and disposable masks efficiently.

Technological advancements also play a key role in shaping the market. CDC research emphasizes the importance of ultrasonic welding and real-time quality control in mask manufacturing. These technologies enhance precision, comfort, and protective performance. Manufacturers are thus adopting modern mask machines with higher output rates and automation features. The combined push from regulatory bodies, public health institutions, and environmental priorities continues to support long-term growth in the face mask machine sector.

Key Takeaways

- The global Face Mask Machine Market is projected to grow from USD 11.7 billion in 2022 to USD 27.4 billion by 2032, at 9.1% CAGR.

- Growing healthcare and pharmaceutical sectors are driving mask production, aided by hospital expansion, government regulations, and rising demand for N95 and surgical masks.

- Multiple industries—construction, manufacturing, and food processing—are increasingly requiring face masks, boosting consistent demand for automated mask-making machines.

- Continuous improvements in automation, precision engineering, and robotics are advancing mask machine technologies, making production faster and more efficient.

- High initial machine costs and the need for skilled maintenance are significant barriers for small businesses entering the mask production market.

- Flat face mask machines held 56.3% market share in 2022, favored in hospitals due to their ability to reduce airborne infection risks.

- Surgical mask machines dominate with a 62% market share in 2022, reflecting strict safety and hygiene standards in global healthcare systems.

- N95 mask-making machines are expected to see the fastest growth, supported by their vital role in clinical and industrial respiratory protection.

- The healthcare and pharmaceutical industries remain the largest end-users, requiring sterile, reliable mask production to combat viral outbreaks and protect staff.

- New technologies, government funding, and innovative materials are unlocking opportunities to boost production efficiency and expand global manufacturing capacity.

- Automation upgrades, portable machines, and custom mask designs are emerging trends improving user flexibility and operational convenience.

- Asia-Pacific leads the market due to established manufacturing hubs, lower production costs, and supportive governmental policies encouraging local production.

- Europe holds the second-largest market share, supported by established companies and stringent healthcare mask manufacturing regulations.

- North America witnessed notable growth in 2022, driven by rising awareness of airborne diseases and a focus on public health readiness.

- Middle East, Africa, and Latin America are expected to experience steady growth, driven by increasing awareness of workplace safety and infection prevention.

Regional Analysis

Asia-Pacific leads the global face mask machine market with a 37.5% revenue share during the forecast period. This dominance is due to the presence of large manufacturing hubs in countries like India, China, and Japan. These regions offer low operational costs and strong industrial infrastructure. Most global manufacturers operate out of Asia-Pacific because of affordable labor and materials. Additionally, this region is a major supplier of hospital equipment, including face masks, which boosts regional demand and production capabilities for face mask machines.

Europe holds the second-largest share in the global face mask machine market. This is mainly attributed to the presence of key players across countries such as Germany, France, and Italy. High-quality respiratory protection is needed due to harmful particulates released from heavy industries. As a result, demand for advanced mask production machinery is rising across Europe. Regional regulations and safety standards are also encouraging investment in efficient and scalable face mask production solutions.

North America is projected to experience significant growth in the face mask machine market. The rise in health awareness and personal hygiene has led to higher demand for protective face masks. In the United States and Canada, consumer behavior has shifted towards adopting high-quality PPE. This trend is driven by health campaigns and post-pandemic precautionary measures. As public and private sectors invest in healthcare infrastructure, demand for automated and efficient face mask production lines is expected to expand steadily in this region.

The Middle East, Africa, and Latin America are expected to witness steady growth during the forecast period. This growth is mainly due to increasing concern about worksite hygiene and respiratory health risks. Many countries in these regions are investing in healthcare manufacturing and safety equipment. Government initiatives and awareness programs are helping to drive demand for high-quality face masks. As a result, the installation of face mask machines is rising, especially in urban and industrial zones where pollution and health risks are more prominent.

Segmentation Analysis

The global face mask machine market is segmented by type into flat face mask machines and vertical face mask machines. In 2022, the flat face mask machine segment held the largest revenue share of 56.3%. These machines are widely used in healthcare settings due to their effectiveness in preventing respiratory infections, including COVID-19. They are disposable and easily accessible, especially in hospitals and clinics. In contrast, vertical face mask machines, which allow the production of various mask types, offer high-volume output and are cost-effective. This segment is expected to remain significant in the coming years.

By application, the surgical mask production segment accounted for the highest revenue share of 62% in 2022. Surgical face mask machines ensure consistency in mask shape, size, and quality. These machines operate in sterilized environments, minimizing the risk of contamination. They are essential in producing masks that meet strict healthcare standards. Meanwhile, the N95 mask production segment is projected to grow at the fastest rate. N95 masks are crucial in industrial and healthcare settings, especially where high-level respiratory protection is required, such as exposure to airborne pathogens or chemical particulates.

Regarding end-users, the healthcare and pharmaceuticals industry segment led the market in 2022 and is expected to retain its dominance. In this industry, face mask machines play a vital role in the mass production of masks that comply with regulatory standards. These machines enhance production efficiency and ensure a consistent supply of quality face masks. The demand is driven by infection control measures and growing awareness of occupational safety. Other industries such as food processing, electronics, and manufacturing also contribute, but to a lesser extent.

By Type

- Flat Face Mask Machine

- Vertical Face Mask Machine

By Application

- N95 Mask Production

- Surgical Mask Production

- Other Applications

By End-User

- Healthcare & Pharmaceuticals Industry

- Food Processing Industry

- Manufacturing Industry

- Electronics Industry

- Other End-Users

Key Players Analysis

Various companies in the market are focusing on organic growth strategies. These include increased product adoption and frequent product launches. Such strategies help companies strengthen their market presence and respond to evolving customer demands. These actions are also aligned with the rising demand for automation and innovation. By introducing new and improved technologies, companies aim to stay competitive. These efforts contribute to sustained market development across different regions. The trend reflects a shift toward efficiency, safety, and compliance in production processes.

In addition to organic strategies, key market players are using inorganic approaches. These include acquisitions, mergers, partnerships, and collaborations. Such initiatives help in expanding distribution channels and technological capabilities. Strategic collaborations often target regional expansion and product diversification. This also allows access to newer markets and customer segments. Prominent companies include Aman Impex, TESTEX INSTRUMENT LTD, Engelmann & Buckham Ltd, 3M Company, SMF Maschinenfabrik GmbH, and Cera Engineering Private Limited. These firms are enhancing their global presence through continuous strategic moves and innovation-led growth.

- Aman Impex

- TESTEX INSTRUMENT LTD

- Engelmann & Buckham Ltd

- Intamac Packaging Systems

- Ajanta Ultraplast Private Limited

- 3M Company

- SMF Maschinenfabrik GmbH

- Cera Engineering Private Limited

- Other Key Players

Emerging Trends

- On-demand compact production systems: Fraunhofer USA has developed a compact face mask machine designed for localized use. This machine produces up to 35 masks per minute, which equals about 2,100 masks per hour. It is ideal for hospitals, clinics, and small medical facilities. These compact systems help reduce dependence on large centralized factories. They are easy to deploy and operate in limited spaces. This trend supports emergency readiness and boosts localized supply chain resilience. The machines also support quick setup and flexible scaling. As demand for face masks remains steady, compact machines offer hospitals a reliable, fast, and efficient mask production solution.

- Integration into Industry 4.0 environments: Face mask machines are being integrated into Industry 4.0 manufacturing setups. In the U.S., several Manufacturing Innovation Institutes adopted smart production tools to meet PPE demand. These automated systems use sensors, real-time data, and robotics. The approach improves speed and reduces human error. Public–private partnerships helped accelerate machine upgrades. As a result, factories shifted quickly to producing high-quality masks during supply shortages. These smart environments allow manufacturers to monitor machine health, reduce downtime, and adjust output based on demand. Industry 4.0 is making face mask production more flexible, connected, and efficient for future health emergencies.

- Focus on mechanical quality and safety testing: There is a rising focus on safety and mechanical testing of face masks. Specialized machines now measure properties such as ear-loop strength, elasticity, and material tear resistance. These machines help verify compliance with global standards like ASTM and ISO. Proper testing ensures that masks remain safe and effective during use. It also helps manufacturers maintain quality and avoid product recalls. Quality testing machines are being integrated into mask-making lines for real-time checks. As standards grow stricter worldwide, automated testing ensures every batch meets health and safety requirements. This trend supports better product consistency and end-user protection.

- Adoption of advanced materials and sustainable filters: There is a shift toward using eco-friendly materials in face mask production. Research supports biodegradable and bio-based options like chitosan and wood-based polymers. These materials can replace synthetic fibers such as polypropylene. The use of sustainable filters helps reduce environmental pollution caused by disposable masks. In addition, biodegradable masks offer a responsible option for healthcare and consumer use. Manufacturers are testing these materials for filtration performance, breathability, and durability. Some sustainable filters already meet standard health protection levels. This trend aligns with growing demand for green products and regulatory pressure to reduce plastic waste.

- Customization through digital manufacturing: Digital manufacturing techniques are enabling custom face mask production. Additive manufacturing, or 3D printing, supports the creation of personalized respirators and small-batch runs. This method allows mask designs to be tailored to individual face shapes or special use cases. Studies show that digitally distributed manufacturing (DDM) is economically viable, especially in hospitals and labs. However, cost depends heavily on labor and material prices. Despite this, 3D printing remains a flexible and fast tool for innovation. It allows for rapid prototyping and local production. This trend is improving access to customized PPE and supporting innovation in mask design.

Use Cases

- Hospital and Field Deployment: Compact face mask machines, like the one developed by Fraunhofer, are designed for local use in hospitals or field settings. These machines can produce up to 2,000 masks per hour. They support decentralized production, which is useful during supply shortages. Hospitals and emergency teams benefit by reducing dependence on central stockpiles. On-demand production improves emergency preparedness. This setup allows healthcare providers to respond quickly to sudden demand spikes during public health emergencies. It also minimizes delivery delays in remote or high-risk areas.

- Factory Safety and Regulatory Compliance: In industrial settings, mask manufacturing must meet quality standards. Tensile testing machines help ensure that masks have the required strength and elasticity. These machines are used to verify compliance with regulations set by the U.S. Occupational Safety and Health Administration (OSHA) and the Food and Drug Administration (FDA). Reliable testing supports worker safety in healthcare and factory environments. Automated machines can conduct repetitive tests accurately. This enables manufacturers to maintain consistent quality and avoid product recalls or regulatory penalties.

- Research and Development of Sustainable Masks: Mask-making equipment is now used in R&D settings to test new materials. Research teams are developing biodegradable mask filters using eco-friendly substances like chitosan. Machines are used to evaluate the filtration performance and environmental safety of these materials. Testing includes breathability, filtration efficiency, and breakdown rate. These trials support the development of sustainable personal protective equipment (PPE). The demand for greener options is growing, especially in hospitals and public health institutions focused on reducing plastic waste.

- Customization in Clinical Settings: Direct digital manufacturing (DDM) allows for the creation of personalized face masks. These masks are tailored to fit a person’s unique facial structure using 3D scanning and design tools. This approach is used in specialized clinical environments. Custom-fit masks improve comfort and sealing, which enhances protection. However, studies show a trade-off between customization and production speed. While DDM offers flexibility, it may not match the high output of conventional machines. Still, it is valuable in specific cases such as pediatric care or patients with facial injuries.

- Pandemic Response and Supply Chain Resilience: During the COVID-19 pandemic, face mask machines played a critical role in emergency response. Government-linked agencies and public–private partnerships repurposed existing factory lines to produce masks. Manufacturing Innovation Institutes in the U.S. led rapid deployment efforts. These machines supported large-scale production in weeks, helping stabilize supply chains. Local mask production reduced reliance on foreign imports. It also increased the national stockpile of PPE. This experience underlined the importance of adaptable machinery in future pandemic preparedness strategies.

Conclusion

The face mask machine market is expected to grow steadily due to strong demand across healthcare, industrial, and public safety sectors. Rising focus on health protection, improved production technologies, and government support are key reasons behind this growth. Manufacturers are adopting automation, smart systems, and sustainable materials to meet both safety and environmental standards. The market also benefits from efforts to build local production and supply chain resilience. As mask use remains important in hospitals and workplaces, reliable and efficient mask-making machines will stay in demand. Overall, the market is well-positioned to support future health needs and evolving regulations through innovation and continuous improvement.

Discuss your needs with our analyst

Please share your requirements with more details so our analyst can check if they can solve your problem(s)