Table of Contents

Overview

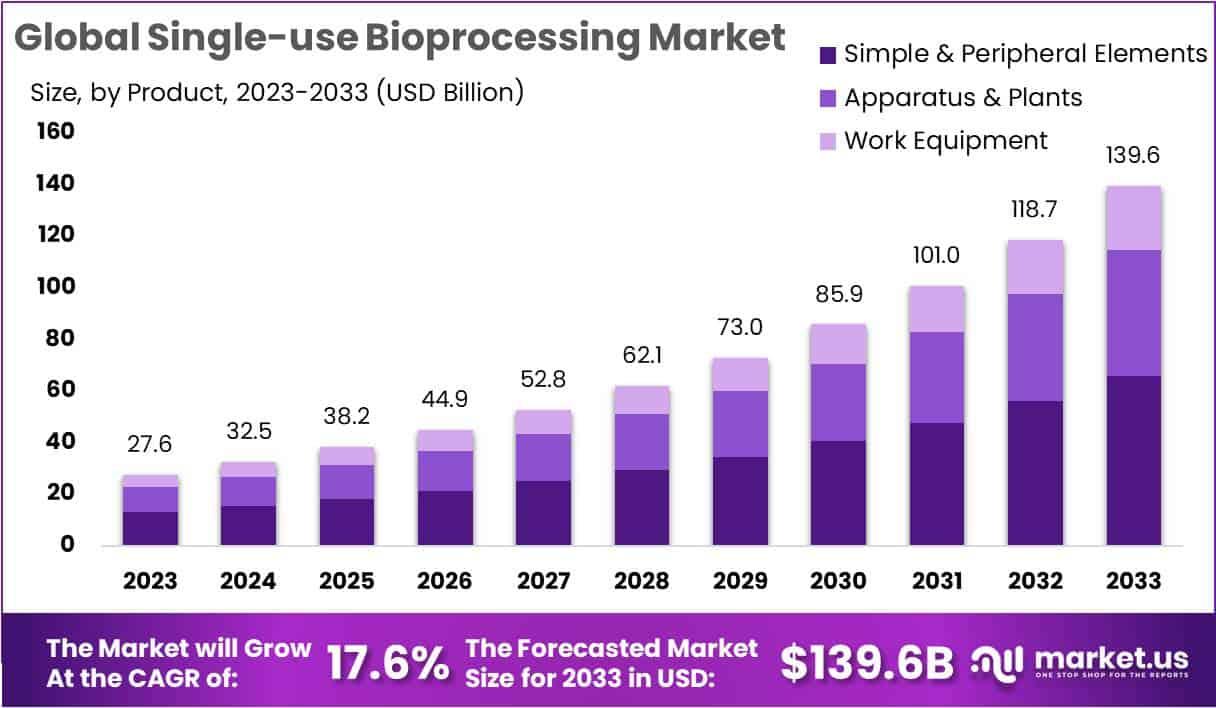

The Single-Use Bioprocessing Market is projected to grow significantly, reaching approximately USD 139.6 billion by 2033, up from an estimated USD 27.6 billion in 2023. This growth reflects a robust Compound Annual Growth Rate (CAGR) of 17.6% from 2024 to 2033. The expansion of this market is primarily attributed to increasing demand for biopharmaceuticals and technological advancements in bioprocessing methods.

The demand for biologics such as monoclonal antibodies, vaccines, and recombinant proteins has surged globally, which has significantly contributed to the growth of the single-use bioprocessing market. These complex biologics require scalable and flexible production solutions, which single-use systems are designed to provide. The expansion of the biologics pipeline and the shift toward personalized medicine have further accelerated the demand for efficient and cost-effective biomanufacturing methods.

One of the key factors driving this market growth is the many advantages that single-use systems offer over traditional stainless-steel equipment. Single-use systems reduce the risk of cross-contamination, lower cleaning and sterilization costs, and allow for quicker turnaround times between production batches. These benefits are especially important in the production of personalized medicines and small-batch therapeutics, where flexibility and efficiency are crucial. As a result, single-use technologies have become more widely adopted in biopharmaceutical manufacturing.

Regulatory support has played an essential role in the rapid adoption of single-use technologies. Regulatory bodies such as the U.S. Food and Drug Administration (FDA) have recognized the advantages of these systems. The FDA reports that over 70% of biotechnology firms are now using single-use systems. This support has encouraged widespread implementation across various stages of biopharmaceutical manufacturing, ensuring that production is both compliant and efficient.

Technological advancements in materials science and automation have further improved the performance and reliability of single-use systems. Innovations such as integrated sensors, real-time monitoring, and genderless connectors have enhanced the sterility, efficiency, and scalability of bioprocessing operations. These technological improvements have made single-use systems more attractive to manufacturers, helping them streamline their production processes while maintaining high standards of quality and safety.

Key Takeaways

- Market Size and Growth: The market was valued at USD 27.6 billion in 2023, projected to reach USD 139.6 billion by 2033, reflecting a CAGR of 17.6%.

- Market Dominance: North America leads the market with a 36.8% share, valued at USD 10.15 billion, driven by strong adoption of single-use bioprocessing technologies.

- Product Leadership: Simple & Peripheral Elements dominate the market, holding over 47.2% of the share, crucial for driving advancements in bioprocessing technologies.

- Workflow Performance: Upstream Bioprocessing holds a significant 55.9% market share, emphasizing its foundational role in ensuring the success of bioproduction processes.

- End-use Significance: Biopharmaceutical Manufacturers command a 56.9% market share, underscoring the importance of single-use technologies in their manufacturing processes.

- Regional Analysis: North America dominates the Single-use Bioprocessing Market with a 36.8% share, valued at USD 10.1 billion, highlighting its market leadership.

Regional Analysis

In 2023, North America holds a dominant position in the Single-use Bioprocessing Market, commanding over 36.8% of the market share and a market value of USD 10.1 billion. This leadership reflects the region’s strong investment in bioprocessing technologies. The substantial market presence underscores North America’s commitment to biopharmaceutical advancements. This focus on innovation has solidified its role as a key player in shaping the global market, with North American companies consistently pushing the boundaries of single-use bioprocessing capabilities.

The dominance of North America is attributed to its extensive biopharmaceutical manufacturing infrastructure, especially in the U.S. The country’s biopharmaceutical R&D sector is also expanding rapidly, fostering greater adoption of single-use technologies. Additionally, many contract manufacturing organizations (CMOs) in the region are integrating disposable systems into their operations. This integration has led to significant investments, further enhancing the region’s standing as a global leader in single-use bioprocessing.

China has emerged as a promising market for single-use bioprocessing in recent years, largely due to its growing biopharmaceutical manufacturing sector. Wuxi Biologics, a prominent contract development and manufacturing organization (CDMO), operates a facility in China that started GMP-compliant production in 2021. With nine 4,000-liter single-use bioreactors, China is poised for rapid growth in this market. India and China are expected to drive the fastest growth rate (CAGR) over the forecast period, making the Asia-Pacific region an emerging powerhouse in bioprocessing technology.

Segmentation Analysis

In 2023, the Single-use Bioprocessing Market saw strong growth driven by key segments. The Simple & Peripheral Elements segment led the market, securing over 47.2% of the share. These basic components were essential in bioprocessing applications, pushing the industry forward. Apparatus & Plants also gained significant traction, contributing to the market’s variety with advanced technologies. Additionally, Work Equipment emerged as a key player, providing tailored solutions that met the industry’s needs and enhancing the flexibility of bioprocessing processes.

Upstream Bioprocessing emerged as the dominant force in the Single-use Bioprocessing Market, capturing over 55.9% of the market share in 2023. This segment’s importance stems from its critical role in the biomanufacturing process, covering cell culture, media preparation, and inoculum development. Fermentation and Downstream Bioprocessing also contributed significantly, driven by the widespread use of single-use technologies. These segments are crucial in producing biologics, ensuring the quality and safety of end products, and reinforcing the efficiency of bioproduction workflows.

The market for Single-use Bioprocessing in 2023 saw Biopharmaceutical Manufacturers take the lead, accounting for over 56.9% of the market share. Their reliance on single-use technologies highlights their importance in biopharmaceutical manufacturing. CMOs & CROs also contributed significantly, underscoring the adoption of these technologies in outsourcing services. In-house Manufacturers and Academic & Clinical Research Institutes further supported the market’s growth, showcasing the broad applicability of single-use bioprocessing technologies beyond traditional manufacturing settings. The sector is poised for further expansion and innovation.

Key Players Analysis

Danaher Corp. operates in the single-use space through its Pall brand, offering a broad range of products such as filtration, separation, and cell culture solutions. Pall’s portfolio includes single-use bioreactors, mixers, tubing, connectors, and sensors. Danaher is heavily investing to expand production capacity and enhance R&D efforts. By providing complete solutions, the company aims to drive adoption across various biomanufacturing processes. Pall’s strong market expertise and ability to customize offerings make it a leading supplier in the single-use technology market.

Thermo Fisher Scientific Inc. provides a diverse selection of single-use products, including storage bags, mixing systems, tubing sets, and bioreactors. The company is known for its advanced single-use sensors and automation equipment. Through strategic partnerships and a robust distribution network, Thermo Fisher maintains a competitive advantage. The company continues to innovate its single-use technologies to optimize biopharmaceutical manufacturing. Thermo Fisher’s global scale, comprehensive product offerings, and strong market presence position it as one of the top players in the single-use market.

Merck KGaA, through its BioContinuum brand, offers a comprehensive portfolio of single-use solutions, including pre-sterilized assemblies, bioreactors, fermenters, and filters. The company’s strengths lie in the flexibility, scalability, and efficiency of its single-use technologies. Merck focuses on providing fully integrated solutions tailored to customer needs. Its deep expertise in the field ensures the delivery of high-quality offerings. By continuing to innovate and address customer-specific requirements, Merck is positioning itself to capture more market share in the single-use technology space.

Market Key Players

- Sartorius AG

- Danaher Corp.

- Thermo Fisher Scientific Inc.

- Merck KGaA

- Avantor Inc.

- Eppendorf SE

- Corning Inc.

- Boehringer Ingelheim International GmbH

- Lonza

- Infors AG

- PBS Biotech Inc.

Conclusion

In conclusion, the Single-use Bioprocessing Market is poised for substantial growth, driven by increasing demand for biologics and the advantages of single-use systems, such as reduced contamination risks and cost savings. Technological advancements and regulatory support are further accelerating market adoption, especially in North America, which remains the market leader. The Asia-Pacific region, particularly China and India, is expected to experience the highest growth rates. Biopharmaceutical manufacturers and contract organizations are the primary users of these technologies, indicating a broad market application. As the industry continues to evolve, innovation and investments in bioprocessing technologies will likely play a key role in shaping its future.

Discuss your needs with our analyst

Please share your requirements with more details so our analyst can check if they can solve your problem(s)