Introduction

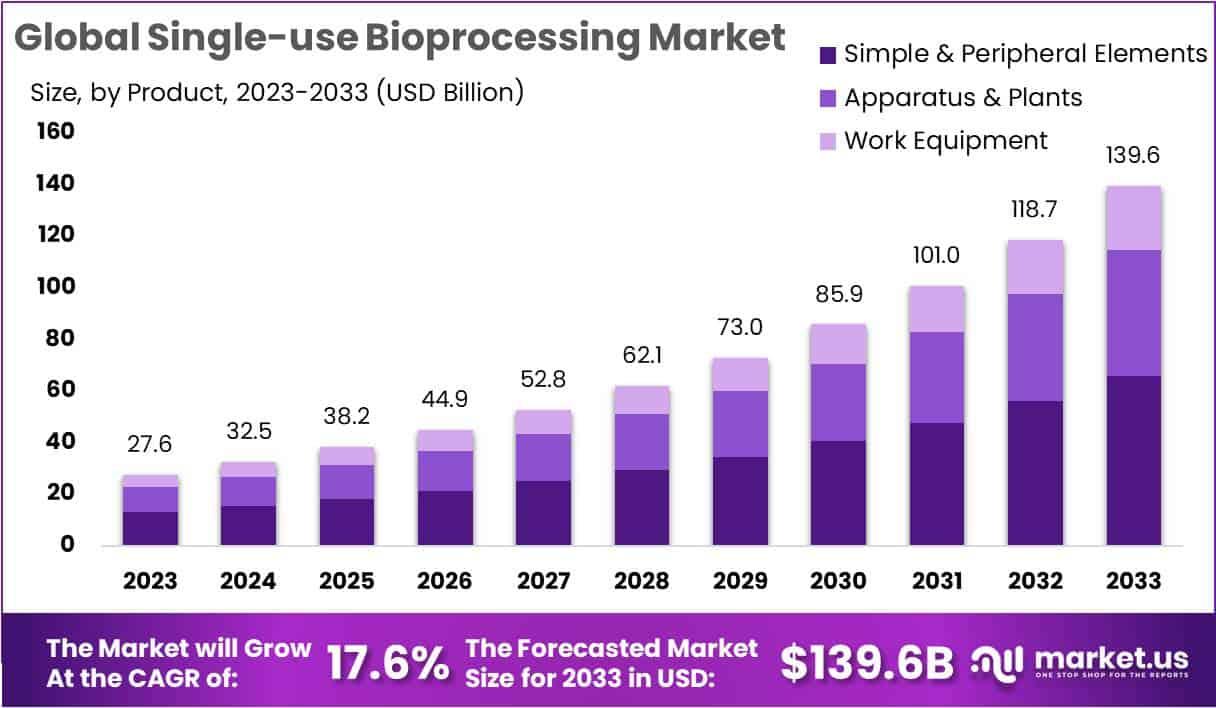

The Single-use Bioprocessing Market Size is poised for significant growth, projected to expand from USD 27.6 billion in 2023 to USD 139.6 billion by 2033. This surge represents a Compound Annual Growth Rate (CAGR) of 17.6% from 2024 to 2033. The market’s growth is propelled by several factors, including technological advancements in automation and integration that enhance the efficiency of bioprocessing systems. These innovations are crucial for producing complex therapies, such as cell and gene treatments and monoclonal antibodies, which are becoming increasingly prevalent in pharmaceuticals.

Educational and training initiatives are also vital in driving the sector’s expansion. The Jefferson Institute for Bioprocessing, unique in North America, merges commercial single-use processing equipment with specialized training. This approach addresses the industry’s skill gap, preparing a workforce adept at meeting growing demands.

Moreover, the shift towards biologics in therapeutic development significantly influences the market. Biologics require sophisticated bioprocessing technologies, boosting the demand for single-use systems that support their production. Additionally, despite concerns over waste generation, these systems are recognized for reducing energy and water usage. This positions them as a sustainable option within the pharmaceutical industry, despite the environmental challenges they present.

Key Takeaways

- In 2023, the market was valued at USD 27.6 billion, projected to rise to USD 139.6 billion by 2033, growing at a 17.6% CAGR.

- North America holds the largest market share at 36.8%, valued at USD 10.15 billion, due to strong adoption of single-use bioprocessing technologies.

- Simple & Peripheral Elements dominate the market with a 47.2% share, crucial in advancing industry technologies.

- Upstream Bioprocessing is the leading workflow with a 55.9% market share, foundational to successful bioproduction.

- Biopharmaceutical Manufacturers are the primary end-users, holding a 56.9% market share, underscoring the importance of single-use technologies in production.

- North America maintains a significant presence in the market, representing 36.8% with a value of USD 10.1 billion.

Regional Analysis

In 2023, North America achieved a significant presence in the Single-use Bioprocessing Market, securing over 36.8% market share and a value of USD 10.1 billion. This leading position underscores the region’s robust adoption of and investment in single-use bioprocessing technologies. North America’s commitment to bioprocessing advancements establishes it as a pivotal player in the industry.

The dominance of North America mainly stems from extensive biopharmaceutical manufacturing and expanding research and development activities in the U.S. The region’s large-scale manufacturing capabilities play a critical role in sustaining its market leadership.

Further investment is evident as numerous North American contract manufacturing organizations integrate disposable technologies into their operations. This trend reflects a broader acceptance and application of single-use systems, which continues to drive regional market growth.

Internationally, Fujifilm Diosynth has invested USD 2 billion in a U.S. facility designed for large cell cultures, equipped with eight 20,000-liter bioreactors. Similarly, Wuxi Biologics commenced operations at its GMP-compliant facility in China in February 2021, featuring nine single-use bioreactors. This global expansion, especially in China and India, indicates a rapidly growing market, poised for the fastest CAGR in the coming years.

Emerging Trends

- Automation and Integration: The shift toward automation and integration is reshaping single-use bioprocessing, particularly beneficial in the production of personalized medicines like cell and gene therapies. These therapies often require multiple small-volume production batches. Automation helps streamline these processes by seamlessly connecting different stages, from bioreactors to filtration systems. This integration enhances efficiency, crucial for the complex workflows involved in personalized medicine.

- Continuous Manufacturing: The trend of continuous manufacturing is gaining traction in the bioprocessing industry. Unlike traditional batch processing, continuous manufacturing involves uninterrupted production, which improves stability and increases productivity. This method ensures more consistent quality in biopharmaceutical products, addressing the industry’s need for more efficient production techniques.

- Sustainability Concerns: As the adoption of single-use systems in bioprocessing increases, so do concerns about their environmental impact. The industry is exploring ways to balance the advantages of single-use technologies, such as lower water and energy consumption, with the challenge of disposing of more plastic waste. Innovations are underway to develop more sustainable materials and effective recycling processes, aiming to reduce the ecological footprint of these technologies.

- Educational and Workforce Development: The Jefferson Institute for Bioprocessing is leading initiatives to bridge skill gaps in the bioprocessing sector. They offer specialized training and education programs tailored to the nuances of biopharmaceutical manufacturing, which increasingly relies on single-use technologies. Such educational efforts are vital for maintaining the sector’s growth and fostering innovation, ensuring a well-prepared workforce to meet the industry’s demands.

Use Cases

- Production of Biologics: Single-use systems play a critical role in the biologics sector, including the production of vaccines and monoclonal antibodies. These systems are key in rapidly setting up and modifying production facilities, which is vital during health crises like pandemics. Their use not only enhances operational flexibility but also reduces downtime between production cycles, significantly boosting responsiveness to global medical demands.

- Development and Manufacturing of Advanced Therapies: In the realm of advanced therapies, such as personalized medicine, single-use bioprocessing technology is invaluable. It supports the swift development and scaling-up of products. Utilizing single-use bioreactors and mixers, manufacturers can produce cell and gene therapies more efficiently. These technologies lower costs, decrease production times, and minimize contamination risks, ultimately enhancing patient safety.

- Research and Development: In research and development, single-use bioprocessing technologies are crucial for maintaining a fast-paced work environment. They allow researchers to run multiple experiments simultaneously without extensive cleaning or setup. This capability accelerates innovation and expedites discoveries in the biopharmaceutical industry, leading to quicker advancements and more efficient research outcomes.

Conclusion

In conclusion, the single-use bioprocessing market is experiencing robust growth due to its crucial role in producing biologics and advanced therapies. Technological enhancements in automation and integration are driving efficiencies across biopharmaceutical manufacturing, streamlining the production of complex therapies. North America’s strategic investments and the adoption of these technologies underline its market leadership, while global expansion, particularly in Asia, signals a broader trend towards embracing single-use systems. Despite environmental concerns, the sector is actively seeking solutions to minimize its ecological impact. As the industry evolves, continued emphasis on workforce training and educational initiatives will be essential to sustain growth and innovation in single-use bioprocessing.

Discuss your needs with our analyst

Please share your requirements with more details so our analyst can check if they can solve your problem(s)