Table of Contents

Overview

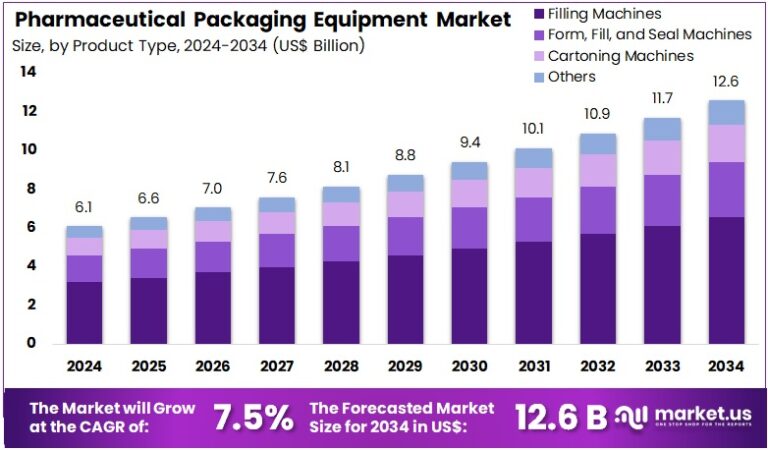

New York, NY – July 31, 2025 : The Pharmaceutical Packaging Equipment Market is expected to grow from US$ 6.1 billion in 2024 to US$ 12.6 billion by 2034, at a CAGR of 7.5% from 2025 to 2034. This growth is driven by the increasing demand for efficient and secure packaging systems. As pharmaceutical production volumes rise, companies seek packaging equipment that supports fast, safe, and accurate output. Regulatory standards also push for higher quality and precision in packaging. This makes advanced, automated equipment essential for compliance and safety.

Pharmaceutical companies are investing in technologies that enhance operational efficiency. Packaging equipment with automation capabilities helps reduce manual labor and speed up production. These systems also minimize human errors and improve overall workflow. Smart packaging solutions are gaining traction for their ability to track and verify medicines during distribution. By adopting digital and connected systems, pharmaceutical manufacturers can ensure product integrity. This is crucial for meeting strict international regulatory requirements and maintaining trust in the supply chain.

Another key growth factor is the rising concern over counterfeit drugs. The pharmaceutical industry faces growing pressure to safeguard products throughout the supply chain. As a result, there is high demand for packaging solutions that support serialization, tamper-evidence, and traceability. Companies are integrating anti-counterfeit technologies into their packaging equipment. These features not only protect brand reputation but also improve patient safety. Innovation in this area is critical to maintain compliance and deliver safe products across global markets.

The market is also shifting toward patient-friendly and sustainable packaging. Consumers increasingly prefer packaging that is easy to open, transport, and dispose of. In response, manufacturers are upgrading equipment to produce eco-friendly and user-centric packaging formats. There is strong interest in recyclable materials and minimal packaging designs. Companies are aligning with global environmental standards by investing in green technologies. These efforts not only reduce waste but also enhance brand image. Sustainability has become a strategic focus for many pharmaceutical packaging firms.

Strategic acquisitions are reshaping the competitive landscape. For example, in February 2021, ProMach acquired Serpa Packaging Solutions, expanding its cartoning and end-of-line packaging capabilities. This move strengthens ProMach’s position in the pharmaceutical and consumer goods sectors. It also reflects a broader trend of consolidation aimed at improving packaging efficiency and innovation. As more companies focus on automation and integrated solutions, the market is expected to see continued technological progress. This evolution supports long-term growth in the pharmaceutical packaging equipment industry.

Key Takeaways

- In 2024, the pharmaceutical packaging equipment market earned US$ 6.1 billion, expected to grow to US$ 12.6 billion by 2034 at 7.5% CAGR.

- Among product types, filling machines dominated the market in 2024, accounting for a strong 52.3% of the total market share.

- Automatic technology was the top choice in 2024, capturing a significant 61.8% share in the pharmaceutical packaging equipment sector.

- Liquid formulations led the formulation segment, contributing the largest revenue share of 56.5% in the global market during 2024.

- Pharmaceutical companies were the primary end-users in 2024, representing a dominant 62.5% of total market revenue.

- North America emerged as the leading regional market in 2024, holding a commanding 43.6% share of global revenue.

Regional Analysis

North America is leading the Pharmaceutical Packaging Equipment Market

North America held the largest revenue share of 43.6% in 2024. This was due to rising drug approvals, vaccine output, and automation in manufacturing. The FDA approved 55 novel drugs in 2023, up 12% from 2022, which increased the demand for advanced packaging solutions. CDC data also showed a 9% rise in vaccine production that year. Chronic diseases are also a major factor. Over 2 million new cancer cases are projected in 2024, requiring secure packaging. Automation is also expanding, with robotic packaging installations growing 15% between 2022 and 2024.

Asia Pacific is expected to experience the highest CAGR during the forecast period

Asia Pacific is projected to grow at the fastest CAGR in the coming years. Growth is driven by government support and rising drug production. India’s PLI scheme allocated US$2 billion in 2023 to expand pharmaceutical manufacturing. China approved 12,000+ generic drugs in 2023, up 20% from the year before, boosting demand for bottling and sealing systems. Southeast Asia saw a 30% rise in vaccine production, according to WHO. Japan reported a 10% increase in biologics approvals in 2024, pushing adoption of aseptic packaging equipment across the region.

Segmentation Analysis

Product Type Analysis

In 2024, the filling machines segment dominated the market with a 52.3% share. This growth is driven by rising demand for liquid and injectable pharmaceutical products. Emerging markets are fueling the expansion of the global pharmaceutical industry, increasing the need for high-capacity filling machines. Advanced features like precision, speed, and flexibility are attracting manufacturers. Moreover, strict regulations around dosing and contamination control are boosting demand for sophisticated equipment. These factors are expected to support continued growth in the filling machines segment over the forecast period.

Technology Analysis

Automatic technology accounted for 61.8% of the market share due to its efficiency and consistency. Automatic systems reduce human error, lower labor costs, and ensure precision in packaging. With rising production volumes and safety concerns, pharmaceutical companies prefer automation over manual methods. These systems integrate seamlessly into broader production lines, enhancing operational efficiency. The growing focus on cost savings and regulatory compliance is pushing manufacturers to adopt automated packaging solutions. This trend is likely to continue as demand for scalable and reliable packaging systems increases globally.

Formulation Analysis

The liquid formulation segment held a 56.5% revenue share due to increasing production of vaccines, biologics, and oral liquids. These products require specialized packaging to ensure sterility, stability, and patient convenience. The rising burden of chronic diseases and demand for injectable medications support this growth. Innovations in liquid packaging technology, including sterile filling and sealing systems, are improving efficiency. As pharmaceutical companies prioritize quality and safety, investment in advanced liquid packaging is expected to grow. This will further expand the liquid formulation segment in the coming years.

End-User Analysis

Pharmaceutical companies led the end-user segment with a 62.5% revenue share. This is due to increasing global demand for packaged drugs and regulatory pressure to maintain product integrity. Companies involved in mass production continue investing in advanced packaging systems to enhance efficiency and compliance. The rise of firms specializing in biologics and high-value drugs also contributes to this demand. As global competition intensifies, pharmaceutical companies are expected to adopt more automated, cost-effective packaging solutions. This shift will likely support sustained growth in this segment throughout the forecast period.

Key Market Segments

By Product Type

- Filling Machines

- Form, Fill and Seal Machines

- Cartoning Machines

- Others

By Technology

- Manual

- Semi-Automatic

- Automatic

By Formulation

- Liquid

- Solid

- Semisolid

- Others

By End-user

- Pharmaceutical Companies

- Contract Manufacturing Companies

Key Players Analysis

Key players in the pharmaceutical packaging equipment market focus on innovation, automation, and product expansion. They develop high-speed, flexible systems that support various drug types and packaging materials. Automation helps improve efficiency, while meeting strict regulatory standards. Many companies now offer eco-friendly and tamper-evident packaging to support sustainability. Regulatory compliance remains a top priority. Firms also strengthen their global presence by forming strategic partnerships with pharmaceutical manufacturers and tech providers, aiming to enhance product offerings and reach emerging markets with growing healthcare needs.

Uhlmann Packaging Systems, based in Germany, is a key player in this market. The company specializes in high-performance, automated packaging lines for tablets and capsules. Its systems are designed for speed, precision, and regulatory compliance. Uhlmann is recognized for its innovative, fully integrated packaging technologies. These solutions streamline production and improve output quality. The company focuses on customization to meet client-specific needs. With a strong global footprint, Uhlmann continues to grow by partnering with pharma firms and offering advanced solutions tailored to modern production demands.

Top Key Players in the Pharmaceutical Packaging Equipment Market

- Uhlmann Group

- Romaco Holding

- Robert Bosch

- MULTIVAC Group

- Marchesini Group

- Korber AG

- M.A. Industria Macchine Automatiche S.p.A.

- Coesia

Emerging Trends

1. Automation Is Becoming the New Standard

Pharmaceutical companies are increasingly investing in automated packaging machines. These systems help reduce human error and improve packaging speed. Automation ensures consistent quality, which is critical for regulatory compliance. With fewer manual steps, companies can also maintain better hygiene and reduce labor costs. Automated systems support high-volume production and allow for better use of resources. They can also detect packaging issues faster, helping avoid product recalls. As demand grows for efficiency and accuracy, automation is quickly becoming a must-have in pharmaceutical packaging.

2. Eco-Friendly Packaging Equipment Is in Demand

Sustainability is becoming a key focus in pharmaceutical packaging. Companies want machines that reduce waste and support recyclable materials. Modern equipment is now being designed to use less energy and minimize material usage. This shift is driven by both environmental concerns and new regulations. Many firms are adopting machines that handle biodegradable or compostable packaging. These systems also reduce excess packaging and optimize material use. As green practices grow more important, sustainable packaging equipment is gaining strong traction in the industry.

3. Flexible Equipment for Multiple Drug Forms

Pharmaceutical packaging needs to be more versatile than ever. Companies are packaging tablets, liquids, creams, and injections using the same equipment. This reduces the need to buy separate machines for each product type. Flexible equipment can switch between different packaging tasks with minimal downtime. This saves time and cuts operational costs. It also supports faster product rollouts, which is key in today’s competitive market. With more diverse drug forms on the rise, packaging flexibility is now a top requirement.

4. Smart Technology Integration in Machines

Packaging machines are getting smarter with the help of new technology. Features like sensors, data tracking, and remote access are becoming common. These tools help operators monitor performance and detect issues early. Smart systems provide real-time feedback, which improves decision-making. They also support predictive maintenance, reducing unexpected breakdowns. Companies can track production data, reduce waste, and ensure quality. This level of control and insight helps meet strict industry standards. As a result, smart technology is reshaping how packaging equipment is managed.

5. Machines for Smaller, Personalized Batches

There is growing demand for personalized medicines and small-batch drugs. This shift requires packaging machines that can handle smaller quantities quickly and efficiently. Traditional large-scale equipment is not suited for this. New systems are now designed to adapt to changing batch sizes with minimal effort. These machines reduce setup time and avoid material waste. They’re ideal for clinical trials, rare disease drugs, and personalized therapies. As precision medicine expands, packaging flexibility for small runs becomes essential.

6. Sterile and Cleanroom-Friendly Equipment

Sterility is a top concern, especially for injectables and sensitive drugs. Packaging equipment must meet strict cleanliness standards. Today’s machines are often built to work in cleanroom environments. They use materials and designs that prevent contamination. This helps ensure drug safety and compliance with regulations. Equipment is also easier to clean and sterilize between uses. As more complex and injectable therapies enter the market, the need for sterile-compatible packaging equipment continues to grow. Cleanroom-ready machines are now a vital part of pharmaceutical production.

Use Cases

1. Tablet and Capsule Bottling

Tablet and capsule bottling machines are essential for modern pharmaceutical packaging. These machines fill bottles with a specific number of tablets or capsules. After filling, they seal the bottles to protect the medicine. Labels are added with important details like dosage and expiry dates. Finally, the bottles are packed into cartons for shipping. This process ensures each bottle is accurate and secure. It also helps prevent errors in pharmacies and hospitals. Automated bottling speeds up production and reduces human mistakes. The result is safe, traceable packaging for patients. This type of equipment is widely used in both large and small pharmaceutical facilities.

2. Liquid Medication Filling

Liquid filling machines are used to package medicines like syrups, eye drops, and injectable solutions. These machines fill each bottle or vial with a precise amount of liquid. They help maintain hygiene by operating in sterile conditions. Spills and contamination are avoided with automated controls. Once filled, the bottles are sealed to keep the medicine safe. Labels are added for easy identification and traceability. These machines are especially useful for high-volume production. They ensure consistency in every batch. For pharmaceutical companies, liquid filling equipment improves safety, speed, and compliance with health regulations.

3. Blister Packaging for Pills

Blister packaging is common for tablets and capsules. Machines create small plastic pockets, place each pill inside, and seal them with aluminum foil. This keeps each pill separate and protected from air, moisture, and light. It also makes dosing easier for patients. The sealed blisters are then placed into cartons for sale. Blister packaging helps extend the shelf life of medicine. It also prevents pills from being mixed up or contaminated. These machines are fast, precise, and help with clear labeling. They are widely used for over-the-counter and prescription drugs in pharmacies.

4. Packaging for Injectable Drugs

Injectable drugs require careful packaging due to their sterile nature. Machines are used to handle vials and ampoules with precision. First, the containers are washed and sterilized. Then they are filled with the drug in a clean environment. After filling, the vials are sealed and inspected for quality. This process ensures there are no leaks or particles. These machines work in highly controlled conditions to meet strict safety standards. Packaging equipment for injectables is vital in producing vaccines and other critical drugs. It ensures product safety, accurate dosing, and long shelf life.

5. Cartoning and Secondary Packaging

After primary packaging, medicines are often grouped into cartons for transport and retail. Cartoning machines take bottles, blister packs, or vials and insert them into labeled boxes. These boxes may also include instruction leaflets for patients. The machines then seal the boxes and print barcodes or batch numbers. This step helps with inventory control and compliance. Cartoning machines handle large volumes efficiently. They also reduce the need for manual labor. Secondary packaging plays a key role in protecting products and preparing them for distribution. It improves traceability and keeps the medicine organized for retailers and hospitals.

6. Tamper-Evident and Safety Seals

Safety is a top priority in pharmaceutical packaging. Many machines now include features to apply tamper-evident seals and child-resistant caps. These seals show if a product has been opened before use. Child-proof caps help prevent accidental consumption by kids. Adding these safety features builds trust with consumers. It also helps companies meet legal and regulatory standards. Machines that apply seals and special caps do so quickly and accurately. They are commonly used for both over-the-counter and prescription medicines. These solutions improve safety and reduce the risk of contamination or misuse.

Conclusion

In conclusion, the pharmaceutical packaging equipment market is growing steadily due to rising demand for safe, efficient, and sustainable drug packaging. With automation becoming the norm, companies are adopting advanced systems to improve speed, reduce errors, and meet strict regulations. The need to prevent counterfeiting, support eco-friendly packaging, and handle diverse drug types is also pushing innovation. Key players are focusing on smart technologies, flexible machines, and sterile-ready systems to meet industry needs. As global healthcare demands rise, the market will continue to evolve. Manufacturers investing in high-quality, versatile, and compliant packaging equipment are well-positioned for long-term success in this fast-moving sector.

Discuss your needs with our analyst

Please share your requirements with more details so our analyst can check if they can solve your problem(s)