Table of Contents

Introduction

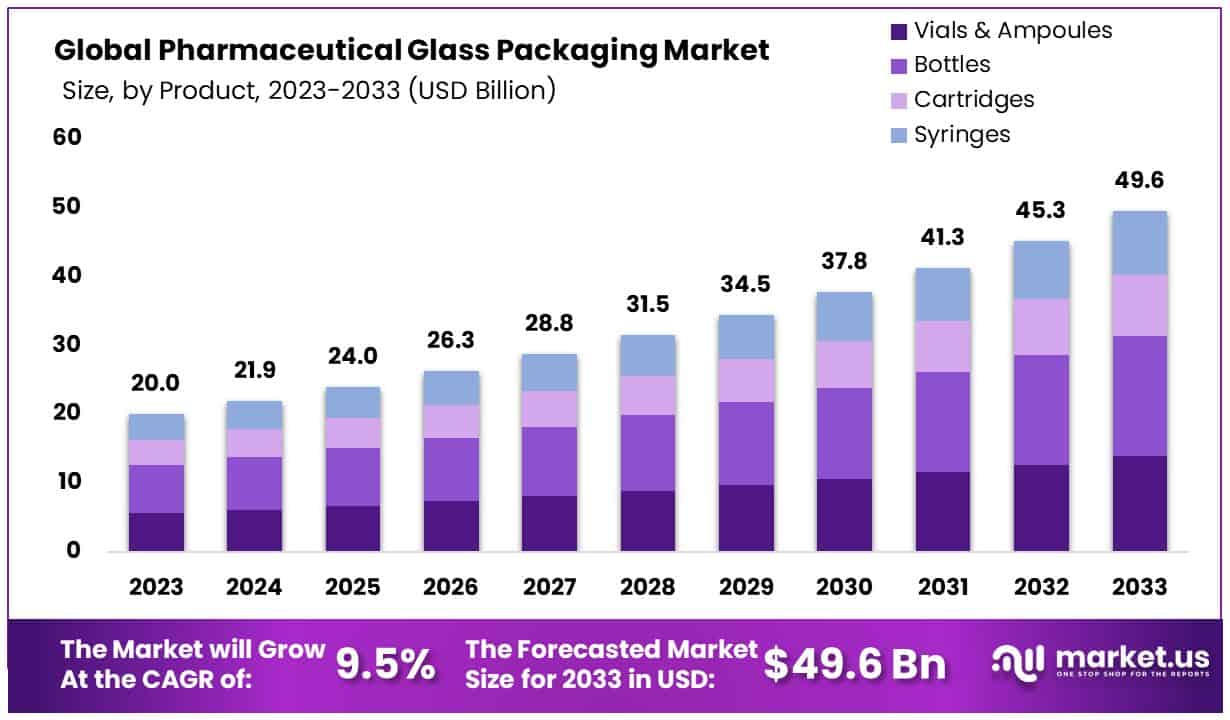

The Global Pharmaceutical Glass Packaging Market is poised for significant expansion, projected to reach around USD 49.6 Billion by 2033, rising from USD 20.0 Billion in 2023. Growing at a strong CAGR of 9.50%, this market benefits from the surging global demand for safe, sustainable, and regulatory-compliant pharmaceutical packaging solutions.

As pharmaceutical innovation accelerates, the industry’s reliance on glass containers—ranging from vials to bottles—continues to increase. The market’s upward trajectory is supported by healthcare spending growth, a rising focus on biologics, and technological advancements in packaging. These elements collectively underscore glass’s role as a critical enabler in global pharmaceutical supply chains.

Furthermore, innovations in coatings and design are enhancing product safety, stability, and sustainability. Such improvements, alongside expanding regulatory emphasis on patient safety, are driving the pharmaceutical glass packaging industry toward a future defined by efficiency, resilience, and environmental responsibility.

Key Takeaways

- Market Value: The market is projected to reach approximately USD 49.6 Billion by 2033, up from USD 20.0 Billion in 2023, registering a CAGR of 9.50%.

- Product Analysis: Bottles dominate the market with a 35.2% share due to their versatility, sustainability, and compatibility with various drug formulations.

- Drug Type Analysis: Generic drugs lead with a 72.1% share, reflecting cost-effectiveness and high global demand.

- Regional Analysis: North America commands a 36.4% share, driven by advanced infrastructure and stringent regulatory frameworks.

- Key Players: Major contributors include Corning Incorporated, Nipro Corporation, and SGD S.A., among others such as Schott AG and Gerresheimer AG.

- Growth Opportunities: Innovation in glass coatings, emerging market expansion, and sustainability trends present major opportunities.

Market Segmentation Overview

The Product Segment is dominated by glass bottles, which account for 35.2% of total market share. Their widespread use in liquid pharmaceuticals, coupled with recyclability, supports sustainability initiatives and ensures safe drug storage, making them a preferred choice among manufacturers.

In terms of Drug Type, generic drugs hold a commanding 72.1% share. Their affordability and rising demand across developing economies continue to boost the need for durable glass packaging solutions that comply with global safety and stability standards.

Drivers

One of the core drivers of market growth is the increasing preference for safe and inert packaging materials. Glass’s chemical stability ensures that pharmaceuticals maintain integrity throughout their shelf life, minimizing contamination risks. As healthcare safety standards rise globally, demand for high-quality glass containers continues to grow.

Another major driver is the expansion of biologics and injectable drugs. These complex formulations require packaging that maintains sterility and precision. Glass syringes and vials serve as essential components in ensuring these products’ safety and efficacy, thus reinforcing glass packaging’s critical role in modern healthcare delivery.

Use Cases

Pharmaceutical glass packaging is crucial in preserving the stability of liquid formulations such as vaccines and syrups. By preventing chemical interactions, glass containers guarantee dosage consistency, which is essential for ensuring patient safety and drug effectiveness in hospitals and clinics.

Additionally, glass prefilled syringes have become indispensable for injectable drug delivery, especially in self-administration contexts. Their design supports accurate dosing, reduces contamination risk, and enhances patient convenience, making them ideal for chronic disease treatments.

Major Challenges

A key challenge faced by the market is the high production cost associated with glass manufacturing. The process demands substantial energy and premium materials, such as borosilicate glass, driving up costs. These financial constraints can deter smaller manufacturers, limiting overall adoption.

Fragility remains another challenge. Despite its advantages, glass is prone to breakage during handling and transportation. This results in product losses and safety risks, requiring advanced protective measures and increasing logistical expenses, which can hinder market scalability.

Business Opportunities

The development of advanced glass packaging technologies presents a promising opportunity. Innovations like low-friction coatings and enhanced barrier properties improve both performance and safety. These solutions help pharmaceutical companies meet evolving regulatory and operational needs while reducing contamination risks.

Emerging markets in Asia-Pacific and Latin America offer vast potential for growth. Rapid healthcare infrastructure expansion and increased drug production in nations like India, China, and Brazil are driving local demand for reliable glass packaging, opening avenues for global players to establish a strong presence.

Regional Analysis

North America leads the global market with a 36.4% share, supported by a robust pharmaceutical ecosystem and rigorous quality regulations. The region’s focus on innovation, combined with FDA-enforced standards, ensures high adoption of advanced glass packaging technologies for drug safety and traceability.

Meanwhile, the Asia-Pacific region represents the fastest-growing market segment. Rising healthcare expenditures, increasing pharmaceutical production, and expanding export activities in China and India contribute to this growth. Government incentives and growing awareness of sustainable practices further accelerate regional market development.

Recent Developments

- February 2024: SGD Pharma launched a new range of Type I injectable vials in collaboration with Corning, featuring a low-friction coating to enhance processing efficiency and reduce contamination risks.

- January 2024: SGD Pharma inaugurated a new siliconisation facility at its Saint-Quentin Lamotte (SQLM) plant in France to expand production of siliconised glass vials.

- January 2024: SCHOTT Glass India began producing amber pharma glass in Gujarat to meet increasing local demand for high-quality packaging.

- January 2024: Corning Incorporated and SGD Pharma jointly announced a INR 500 crore investment to establish a pharmaceutical glass packaging plant in Telangana, India, with production scheduled for Q1 2025.

- October 2023: Stoelzle Pharma unveiled its PharmaCos packaging line at CPHI Barcelona 2023, introducing innovative packaging solutions for healthcare and wellness applications.

Conclusion

The Pharmaceutical Glass Packaging Market stands at the forefront of the global healthcare transformation. With a projected valuation of USD 49.6 Billion by 2033 and a healthy 9.50% CAGR, the market is evolving through innovation, sustainability, and stringent regulatory adherence. As demand for biologics, injectables, and eco-friendly packaging rises, glass packaging remains the industry’s preferred choice for its unmatched safety, inertness, and recyclability. The convergence of technological innovation, regulatory advancement, and regional expansion will continue to shape the sector’s future, positioning it as a cornerstone of pharmaceutical integrity and patient safety worldwide.

Discuss your needs with our analyst

Please share your requirements with more details so our analyst can check if they can solve your problem(s)