Table of Contents

Introduction

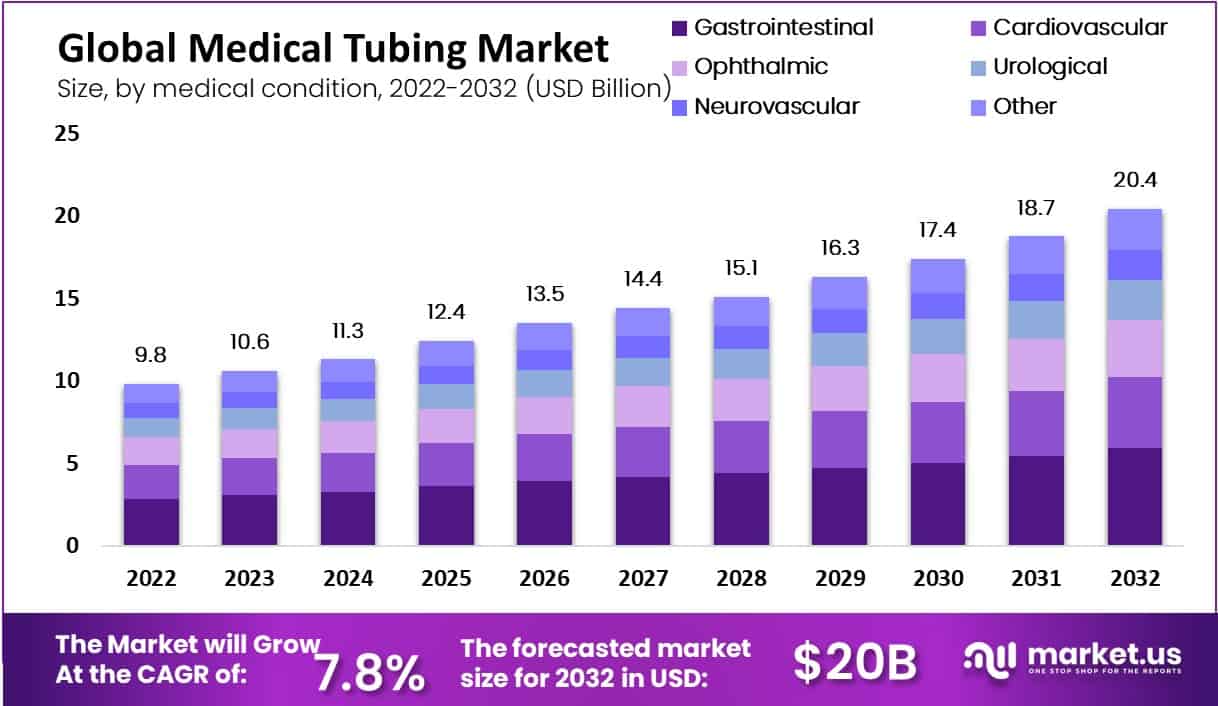

The global medical tubing market, valued at USD 9.8 billion in 2022, is projected to expand to approximately USD 20.4 billion by 2032, with an estimated compound annual growth rate (CAGR) of 7.8% from 2023 to 2032. This growth is predominantly fueled by increasing healthcare expenditures worldwide, particularly in hospital and outpatient services, which demand enhanced medical tubing for various surgical and medical procedures. Additionally, the expansion of hospital capacities globally necessitates more sophisticated medical tubing solutions, directly correlating with increased medical device requirements.

Technological advancements in medical device manufacturing, especially in emerging economies such as India, have significantly propelled the medical tubing sector. The advent of complex medical devices requiring intricate tubing solutions, coupled with heightened R&D investments, supports this growth trajectory. Furthermore, government initiatives in these regions aim to bolster domestic manufacturing, reduce import dependency and enhance the sector’s growth through favorable policies and increased healthcare budget allocations.

Chronic diseases and an aging population worldwide necessitate continuous advancements in medical devices, including medical tubing essential for long-term and home healthcare. This need aligns with rising healthcare investments in durable medical equipment, reflecting the sector’s adaptation to global health challenges. Moreover, regulatory reforms and international cooperation efforts are enhancing the export capabilities of medical tubing manufacturers, improving their global market presence and competitiveness.

Recent strategic developments in the industry include Nordson’s acquisition of Atrion Corporation in June 2024 for approximately $800 million, aimed at strengthening its healthcare portfolio in medical infusion and cardiovascular solutions. This acquisition is strategically valued at about 15 times Atrion’s EBITDA, highlighting the financial robustness of the deal. Additionally, TE Connectivity’s contemplation of divesting its medical contract manufacturing business in May 2024, which could value the segment at over $2 billion, aligns with its strategy to optimize operations.

In late 2023, notable activities included ZARYS International Group’s participation in MEDICA, marking a decade of continuous engagement with the medical community, and Freudenberg Medical’s expansion of its Galway facility. This expansion, which increased the plant’s capacity by 50% and created 100 new jobs, is targeted at boosting production of metal components for minimally invasive surgery catheters. Such developments not only enhance production capabilities but also demonstrate the sector’s dynamic response to increasing global demand.

Key Takeaways

- In 2022, the Polyvinyl Chloride (PVC) segment led the market with a 29.3% share based on material composition.

- The gastrointestinal segment held the largest market share at 29% by material conditions.

- Disposable tubing was the most utilized application, claiming a 31% market share.

- Hospitals were the primary end-users, dominating the market with a 43% share.

- North America led in revenue in 2022, holding a 39% market share.

- The Asia-Pacific region is expected to grow rapidly due to affordable pricing and an increase in medical facilities.

Medical Tubing Statistics

- In the U.S., around 50,000 patients use ventilators every day.

- About 40% of ICU patients need mechanical ventilation.

- Ventilator-associated pneumonia affects up to 28% of ventilated patients.

- The risk of ventilator-associated pneumonia rises by 1-3% each day on a ventilator.

- Mechanical ventilation duration for adults is typically 4-7 days.

- Ventilator-induced diaphragmatic dysfunction affects 30-40% of ventilated patients.

- Mortality rates for ventilated patients range from 35% to 60%.

- Noninvasive ventilation has an 80% success rate in some patient groups.

- During COVID-19, ventilator production increased by over 500% in some countries.

- The U.S. Strategic National Stockpile had 16,600 ventilators during COVID-19, deemed insufficient.

- Invasive mechanical ventilation can damage vocal cords in up to 50% of patients.

- About 20–30% of ventilated patients develop acute respiratory distress syndrome (ARDS) in the ICU.

- 10% to 40% of mechanically ventilated patients need a tracheostomy.

- Around 800,000 patients in the U.S. need mechanical ventilation annually, involving extensive use of medical tubing.

- Managing mechanical ventilation with medical tubing in COPD patients can have a mortality rate of 10-40%.

- In 2022, the global medical tubing market was valued at $9.8 billion.

- By 2023, the market is expected to grow to $10.6 billion.

- In 2024, the market size is projected to be $11.3 billion.

- By 2025, the market will increase to $12.4 billion.

- In 2026, the market is forecasted to reach $13.5 billion.

- By 2027, it is projected to grow to $14.4 billion.

- In 2028, the market size is expected to be $15.1 billion.

- By 2029, the market will increase to $16.3 billion.

- In 2030, the market is forecasted to reach $17.4 billion.

- By 2031, it is projected to grow to $18.7 billion.

- In 2032, the market size is expected to be $20.4 billion.

- The market is projected to grow at a compound annual growth rate (CAGR) of 7.8% from 2022 to 2032.

Emerging Trends

- Increased Utilization in Minimally Invasive Procedures: Medical tubing is increasingly integral to minimally invasive surgeries, which are preferred for their less invasive nature and quicker patient recovery times. These tubes facilitate various functions, such as administering medications, withdrawing fluids, or serving as conduits for miniature surgical instruments. As the healthcare industry continues to shift towards less traumatic surgical methods, the demand for high-quality, reliable medical tubing is expected to grow, enhancing both the efficacy and safety of these procedures.

- Advancements in Material Science: Innovation in material science is revolutionizing medical tubing by developing new materials that enhance biocompatibility, flexibility, and durability. Silicone and polyurethane, known for their safety and reliability, are being further enhanced to minimize patient risk and improve overall clinical outcomes. This trend not only supports the effectiveness of medical devices but also addresses the increasing regulatory scrutiny regarding patient safety and device performance.

- Customization and Flexibility: The evolving needs of various medical specialties are driving a trend towards customized medical tubing solutions. Manufacturers are now offering tubes that are tailored to meet the specific requirements of different medical procedures, from intricate cardiovascular surgeries to routine diagnostic applications. This customization enables healthcare providers to perform more specialized and effective treatments, reflecting a broader move towards personalized medicine.

- Integration with Smart Technology: The integration of smart technologies into medical tubing is transforming its functionality. Advanced tubing now includes embedded sensors that monitor flow rates and detect blockages, significantly improving the safety and efficiency of medical devices. This technological enhancement supports real-time data monitoring, pivotal for critical care, and represents a leap forward in medical device engineering.

- Sustainability Focus: Environmental sustainability is becoming a priority in the medical tubing industry, prompting manufacturers to adopt greener practices and develop more sustainable materials. Efforts are focused on reducing the environmental impact through improved recyclability and waste reduction strategies. This shift not only addresses global environmental concerns but also aligns with the increasing regulatory and consumer demand for sustainable healthcare solutions.

Use Cases

- Drug Delivery Systems: Medical tubing serves an indispensable role in targeted drug delivery systems. By facilitating the precise administration of medication directly to specific areas within the body, these tubing systems enhance both the effectiveness and the control over the drug delivery process. This precision is crucial in treatments where localized medication is necessary for optimal outcomes, making medical tubing a key component in advanced pharmaceutical applications.

- Catheters and Cannulas: In the realm of medical devices, medical tubing is fundamental to the functionality of catheters and cannulas. These tubes are critical across various medical disciplines, including cardiovascular and neurovascular care. They enable not only the administration of fluids and medications but also the performance of diagnostic procedures and surgeries, thereby playing a crucial role in patient treatment protocols.

- Dialysis Equipment: For patients undergoing dialysis, medical tubing is vital. It is specifically designed to ensure the safe and efficient movement of blood between the patient and the dialysis machine. This tubing must meet stringent standards to handle blood effectively, prevent contamination, and withstand regular use. Its reliability is essential for the critical process of dialysis, which many patients depend on regularly.

- Respiratory and Anesthesia Applications: Medical tubing is extensively utilized in respiratory and anesthesia applications. Its design ensures that it can provide secure airway management and deliver gases with precision. This is crucial in settings that require the maintenance of open airways and the accurate administration of anesthetic gases during medical procedures, highlighting the tubing’s importance in patient care and safety.

- Smart Catheters: The integration of sensors into medical tubing has led to the development of smart catheters. These innovative devices offer real-time data during medical procedures, enhancing the accuracy and safety of interventions. By providing continuous feedback to medical professionals, smart catheters facilitate improved patient monitoring and tailored treatment approaches, showcasing the evolving intersection of technology and healthcare.

Conclusion

The global medical tubing market is poised for significant growth, driven by rising healthcare expenditures and technological advancements in medical device manufacturing. The increasing demand for sophisticated medical tubing in response to the expansion of healthcare facilities worldwide supports a robust growth trajectory. Innovations in material science and the integration of smart technologies are set to revolutionize medical tubing applications, enhancing safety and efficiency. Additionally, the market benefits from a focus on sustainability and customization to meet specific medical needs. With these factors propelling the market forward, the medical tubing sector is expected to continue its upward trend, meeting both current and future healthcare demands effectively.

Discuss your needs with our analyst

Please share your requirements with more details so our analyst can check if they can solve your problem(s)