Table of Contents

Overview

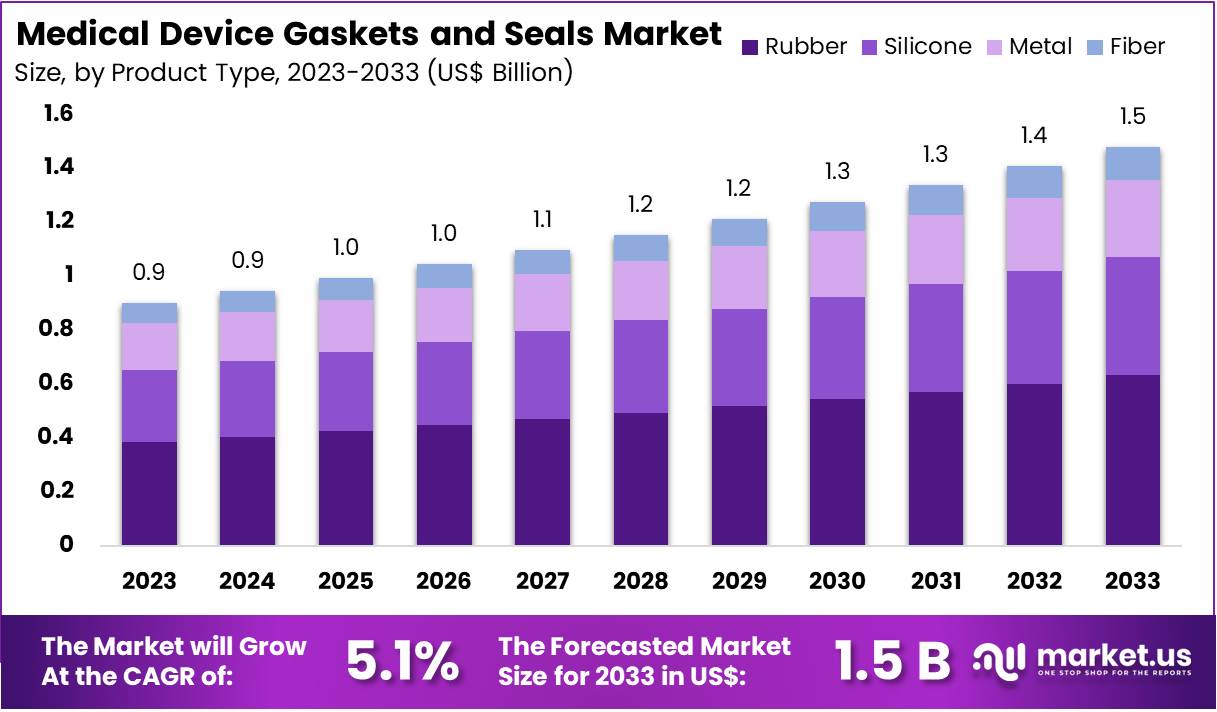

New York, NY – Aug 11, 2025: The Global Medical Device Gaskets and Seals Market is projected to grow from US$ 0.9 Billion in 2023 to around US$ 1.5 Billion by 2033. This represents a CAGR of 5.1% during the forecast period from 2024 to 2033. North America leads the market with over 39.4% share, valued at US$ 0.4 Billion in 2023. The region benefits from advanced healthcare infrastructure and high demand for reliable medical technologies. Regulatory standards also support innovation and quality assurance in gasket and seal manufacturing.

The growing demand for high-performance medical devices is fueling market expansion. Gaskets and seals ensure safety and reliability by preventing fluid leaks, contamination, and equipment failure. They play a crucial role in devices that handle sensitive biological materials. Hospitals and diagnostic labs require equipment with durable sealing components. As medical technologies become more precise, the need for tailored sealing solutions continues to rise. These components help maintain device integrity and extend operational lifespan in demanding clinical environments.

Increasing use of complex devices such as infusion pumps, imaging systems, and surgical tools has boosted the demand for durable seals. These devices often operate under challenging conditions, requiring gaskets that resist wear and withstand sterilization. Custom-fit seals reduce maintenance and enhance device safety. In turn, this supports better patient outcomes and operational efficiency. As the global healthcare system invests in next-generation technologies, demand for advanced gasket materials and designs will continue growing across multiple care settings.

In January 2021, Kaman Corp. expanded its medical device capabilities by acquiring Bal Seal Engineering. This move added precision sealing products to its portfolio, strengthening its position in the healthcare sector. Bal Seal specializes in high-performance seals for surgical and implantable applications. The acquisition aligns with rising demand for precision-engineered components. Sealing systems must perform consistently in sterile and variable-use conditions. Companies are now focusing more on product integration, reliability, and patient safety, where gaskets and seals are core components.

As devices shrink and become more complex, sealing requirements are evolving. Manufacturers are adopting advanced materials like silicone, thermoplastics, and elastomers. These materials meet strict biocompatibility and sterilization requirements. The rise of wearable and implantable devices creates additional demand for lightweight, flexible sealing components. Regulatory compliance and safety standards continue to tighten globally. This drives innovation in design and materials. The trend presents opportunities across infusion systems, portable monitors, and diagnostic platforms where performance under pressure is critical.

Key Takeaways

- In 2023, the medical device gaskets and seals market reached US$ 0.9 billion and is expected to grow to US$ 1.5 billion by 2033.

- The market is growing at a steady CAGR of 5.1%, driven by rising demand for durable, high-performance components in medical devices.

- Among product types, rubber dominated in 2023, capturing 42.7% market share due to its flexibility, cost-effectiveness, and compatibility with medical applications.

- Based on application, diagnostic equipment led with a 46.4% share, reflecting the need for secure sealing in sensitive, precision-driven diagnostic systems.

- North America held the dominant regional position in 2023, accounting for 39.4% of the global market, supported by advanced healthcare infrastructure and innovation.

Regional Analysis

North America currently leads the global Medical Device Gaskets and Seals Market, holding a dominant 39.4% revenue share in 2023. This leadership is driven by strong demand for high-performance medical components and continuous advancements in medical technology. In 2022 alone, the U.S. FDA approved 41 new medical devices, reinforcing the region’s global influence. Factors such as a growing aging population, rising chronic disease prevalence, and the need for safer, more durable medical devices are fueling market growth. Additionally, manufacturers are innovating biocompatible and sterilization-resistant materials to meet evolving healthcare standards.

Meanwhile, the Asia Pacific region is expected to register the highest CAGR during the forecast period, supported by rapid healthcare infrastructure development and increasing medical device usage. Countries like China, Japan, and India are experiencing growing demand for advanced healthcare technologies. In 2023, China’s NMPA received over 13,000 Class II and III device-related applications, underscoring the region’s expanding medical sector. As healthcare investments rise and regulatory frameworks strengthen, the demand for reliable, cost-effective gaskets and seals is accelerating particularly across diagnostic equipment, surgical tools, and patient monitoring systems.

Segmentation Analysis

In 2023, the rubber segment dominated the medical device gaskets and seals market with a 42.7% share, driven by its critical role in ensuring device safety and performance. Rubber offers flexibility, chemical resistance, and durability, making it ideal for a wide range of medical devices such as infusion pumps, syringes, and respiratory systems. The rising use of disposable medical devices, which demand effective sealing to prevent contamination, is further boosting demand. Rubber’s cost-efficiency and ability to meet strict hygiene standards position it as a preferred material in healthcare applications.

Diagnostic equipment emerged as the leading application segment, capturing 46.4% of the market in 2023. This is attributed to the growing need for accurate, contamination-free diagnostic tools like ultrasound systems and glucose monitors. Seals in these devices help maintain system integrity while supporting regulatory compliance. With chronic diseases on the rise and greater emphasis on early diagnosis, demand for high-performance diagnostic systems is increasing. As a result, the requirement for precise and reliable gaskets and seals is expected to grow, driven by advancements in diagnostic technologies and heightened focus on patient safety.

Key Players Analysis

Leading players in the medical device gaskets and seals market are focused on innovation and strategic expansion to strengthen their competitive edge. These companies are actively developing advanced sealing technologies using biocompatible and sterilizable materials to meet stringent industry standards. Expanding global manufacturing capabilities is a key priority, allowing them to support the growing needs of medical device manufacturers worldwide. Strategic collaborations with OEMs and contract manufacturers further enable market penetration, while strict quality control measures ensure product safety and reliability across applications.

Saint-Gobain stands out as a major player in this market, leveraging its deep material science expertise to create high-performance, customized sealing solutions. Its products serve a wide range of applications, from diagnostic systems to implantable devices. The company emphasizes innovation and regulatory compliance to meet evolving customer needs. With a strong global manufacturing presence, Saint-Gobain continues to expand its influence through strategic partnerships and technological upgrades, reinforcing its position as a trusted supplier in the medical device industry.

Emerging Trends

- Rising Demand for Biocompatible Materials: There is a growing focus on using biocompatible materials in medical device gaskets and seals. Materials like silicone and elastomers are gaining popularity because they are safe for use inside the human body. These materials help reduce allergic reactions and are non-toxic. They are also flexible and resistant to harsh cleaning agents, making them suitable for both implantable and external devices. As more devices come into contact with human tissue, manufacturers are prioritizing materials that do not cause irritation. This trend is helping improve patient safety and performance. Biocompatibility has now become a key factor in product development for medical seals.

- Miniaturization of Medical Devices: Medical devices are getting smaller, smarter, and more portable. This includes tools like wearable heart monitors, insulin pumps, and implantable sensors. As devices shrink, the need for compact yet reliable seals is increasing. These mini seals must block out fluids, dust, and air without taking up much space. At the same time, they must remain durable under constant use. Manufacturers are developing high-precision seals that perform well in tight spaces. This trend supports innovation in next-generation medical wearables. It also helps make medical technology more user-friendly and accessible for at-home care and continuous health monitoring.

- High-Temperature and Chemical-Resistant Seals: Medical equipment is often cleaned using high-temperature sterilization or harsh disinfectants. Traditional seals can wear out under these conditions. That’s why there’s a rising demand for seals that can resist both heat and chemicals. Hospitals and clinics rely on sterilization to prevent infections, so seals must hold up during repeated cleaning cycles. Materials like advanced silicones and thermoplastics are becoming more common. These seals protect sensitive internal components from damage while maintaining performance. This trend ensures devices stay safe and functional even in tough hospital environments. It also helps extend the life of reusable medical tools.

- Growth of Single-Use and Disposable Devices: Hospitals are increasingly using single-use medical devices to reduce the risk of infections. These devices are designed for one-time use and then safely discarded. Even though they’re disposable, they still need strong, effective seals. The seals must prevent leaks, maintain sterility, and meet safety standards—while remaining affordable. Manufacturers are focusing on cost-effective materials that can be mass-produced without sacrificing performance. This trend supports the healthcare industry’s shift toward faster, safer, and cleaner care. It also reduces the burden of cleaning and ster

Use Cases

- Infusion Pumps: Infusion pumps deliver precise doses of medication to patients in hospitals and at home. These devices serve over 1 million patients every year. Gaskets and seals inside the pump prevent fluid leaks and ensure accurate drug delivery. A failed seal could cause under- or over-dosing, which may harm patients. That’s why high-quality sealing is essential in these devices. The seals must also withstand constant operation and fluid pressure. Manufacturers rely on materials that offer flexibility, chemical resistance, and long-term durability. Seals help maintain safety, reduce maintenance, and improve treatment outcomes in modern infusion systems.

- Surgical Instruments: Reusable surgical tools are exposed to high temperatures during cleaning and sterilization. Some go through heat above 120°C to ensure safety and hygiene. Gaskets and seals used in these tools must survive repeated sterilization without breaking down. They must also resist chemicals used in hospital-grade disinfectants. A poor-quality seal can cause contamination or failure during surgery. Medical-grade elastomers and silicone seals are common in these tools. They protect joints and movable parts while maintaining cleanliness. These seals support longer instrument life and reduce infection risks in operating rooms.

- Diagnostic Equipment: Diagnostic devices, such as blood analyzers and ultrasound machines, perform hundreds of tests daily in labs and hospitals. These machines use seals to protect sensitive electronics from fluids, dust, and air. Any contamination can lead to faulty results or costly repairs. Seals ensure accurate performance and longer device life. They also support smoother maintenance and fewer breakdowns. Reliable sealing systems are especially important in high-throughput environments. As demand for fast, accurate diagnostics grows, the need for durable, high-performing seals becomes more critical in healthcare settings.

- Implantable Medical Devices: Devices like pacemakers, cochlear implants, and insulin pumps stay inside the body for years. These devices need seals that last 10 years or more without failing. The seals must block body fluids from reaching sensitive electronic components. They also must be biocompatible to avoid causing harm to the body. If the seal fails, it can lead to device failure and serious health risks. Manufacturers use advanced materials like medical-grade silicone and fluoropolymers for long-term performance. These seals help protect patient safety and ensure consistent device functionality throughout the product’s lifetime.

FAQs on Medical Device Gaskets and Seals

1. What are medical device gaskets and seals?

Ans:- Medical device gaskets and seals are components used to prevent leakage, contamination, and component damage in medical equipment. They ensure airtight or fluid-tight enclosures and help maintain sterility and safety.

2. Why are gaskets and seals important in medical devices?

Ans:- They protect internal parts from fluids, dust, and air. This ensures the device functions correctly, prevents infections, and meets safety and regulatory standards.

3. Which materials are commonly used for these components?

Ans:- Common materials include silicone, rubber, thermoplastics, and fluoropolymers. These materials are selected for their flexibility, biocompatibility, and resistance to chemicals and heat.

4. Are medical gaskets and seals reusable?

Ans:- It depends on the application. Some are reusable and designed to withstand multiple sterilization cycles, while others are single-use, especially in disposable medical devices.

5. What types of devices use these gaskets and seals?

Ans:- They are used in infusion pumps, surgical tools, diagnostic machines, implantable devices, and wearable medical electronics.

6. What is driving the growth of the medical device gaskets and seals market?

Ans:– Growth is driven by rising healthcare demand, miniaturization of devices, regulatory focus on safety, and increasing use of disposable and implantable technologies.

7. Which region dominates the market?

Ans:- North America currently leads the market, thanks to advanced healthcare systems, FDA approvals, and strong medical device manufacturing infrastructure.

8. Which segment leads by product type?

Ans:- Rubber gaskets and seals dominate the market due to their durability, flexibility, and cost-effectiveness across various medical applications.

9. Which application segment holds the largest share?

Ans:- Diagnostic equipment holds the largest market share, as reliable sealing is crucial for preventing leaks and contamination in lab and imaging tools.

10. What are some challenges in the market?

Ans:- Challenges include meeting strict regulatory standards, developing biocompatible materials, ensuring long-term durability, and managing manufacturing costs.

Conclusion

The global medical device gaskets and seals market is on a steady growth path, projected to increase from US$ 0.9 billion in 2023 to approximately US$ 1.5 billion by 2033 at a 5.1% CAGR. This expansion is driven by rising demand for high-performance, biocompatible, and sterilization-resistant sealing components in a variety of advanced medical devices.

North America currently leads due to strong healthcare infrastructure and regulatory support, while Asia Pacific is emerging rapidly due to increased medical device usage and healthcare investments. As medical technologies become more compact and sophisticated, the need for reliable, long-lasting sealing solutions continues to rise positioning gaskets and seals as vital components in ensuring safety, performance, and innovation across the global healthcare landscape.

Discuss your needs with our analyst

Please share your requirements with more details so our analyst can check if they can solve your problem(s)