Table of Contents

Overview

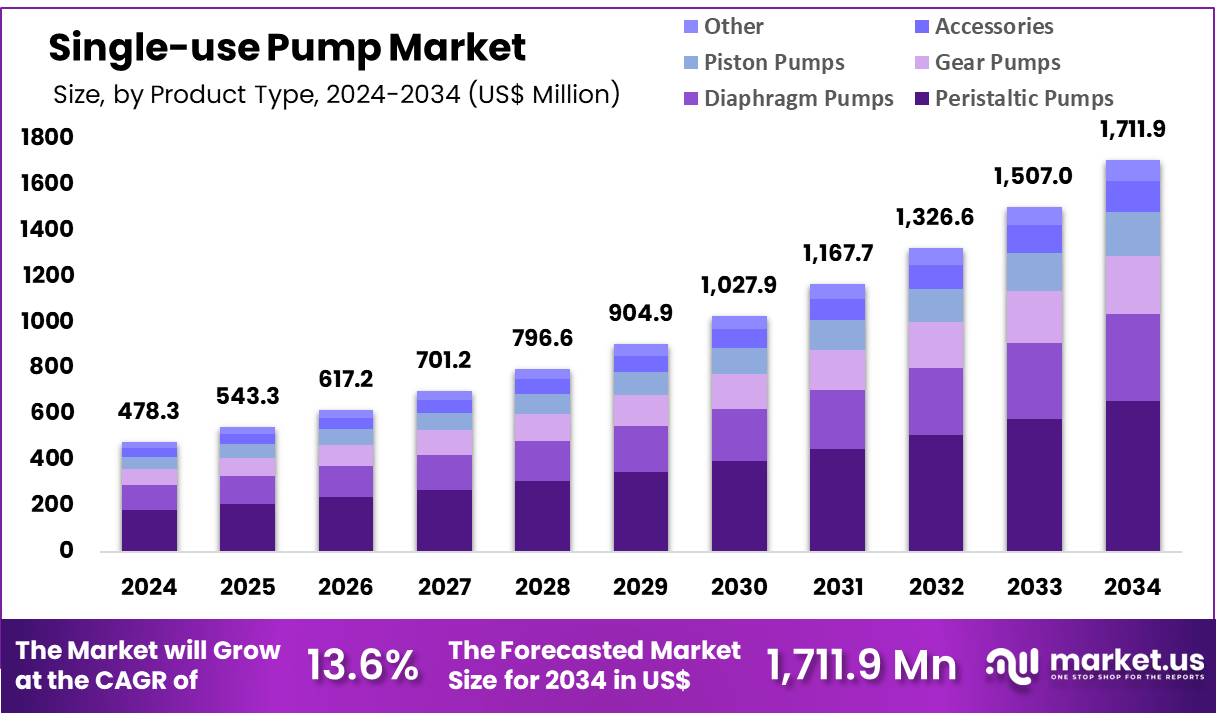

New York, NY – Nov 24, 2025 – Global Single-use Pump Market size is expected to be worth around US$ 1711.9 Million by 2034 from US$ 478.3 Million in 2024, growing at a CAGR of 13.6% during the forecast period from 2025 to 2034. In 2024, North America led the market, achieving over 43.4% share with a revenue of US$ 207.5 Million.

The single-use pump market has been witnessing steady adoption as industries shift toward flexible, contamination-free, and cost-efficient fluid-handling systems. Demand has been driven primarily by the biopharmaceutical and biotechnology sectors, where the need for sterile processing and rapid production changeovers has increased. The growth of the market has been attributed to rising bioprocessing activities, expansion of biologics manufacturing, and the increasing preference for disposable equipment to reduce cleaning and validation requirements.

Single-use pumps are designed to handle sensitive fluids with minimal risk of cross-contamination. These systems offer advantages such as reduced downtime, improved operational efficiency, and enhanced product safety. Their use has become prominent in applications including upstream and downstream bioprocessing, vaccine production, cell culture transfer, and sampling. In addition, growing interest in personalized medicine and small-batch manufacturing has strengthened the adoption of single-use technologies across global facilities.

The market has been characterized by continuous innovation, with manufacturers focusing on improved pump accuracy, material compatibility, and scalable designs suitable for both pilot and commercial operations. Increased investments in biopharma infrastructure and the shift toward modular manufacturing facilities have further supported market penetration.

North America and Europe have accounted for a major share due to advanced healthcare systems and strong biotechnology pipelines, while Asia-Pacific has been experiencing rapid expansion driven by rising pharmaceutical outsourcing. Overall, the single-use pump market is expected to grow steadily as industries continue to prioritize operational flexibility, sterility, and reduced production costs

Key Takeaways

- The global single-use pump market is projected to reach US$ 1,711.9 million by 2034, rising from US$ 478.3 million in 2024.

- The market is anticipated to grow at a CAGR of 13.6% during the forecast period 2025–2034.

Based on product type, the peristaltic pumps segment dominates the landscape, contributing approximately 38.5% of total revenue. - In material usage, polypropylene accounts for the largest share, representing around 64.2% of the market.

By end use, the pharmaceutical and biopharmaceutical sector holds the leading position with about 31.9% of overall demand. - Regionally, North America led the market in 2024, capturing over 43.4% of global revenue, valued at US$ 207.5 million.

Regional Analysis

In 2024, North America maintained a leading position in the single-use pump market, accounting for over 43.4% of the global share and reaching a market value of US$ 207.5 million. This dominance has been supported by the region’s advanced biopharmaceutical manufacturing landscape. Growing investment in biologics, cell therapies, and personalized treatment modalities has elevated the need for sterile, contamination-free fluid management solutions.

The strong presence of major pharmaceutical and biotechnology companies in the U.S. and Canada has further strengthened market expansion. These organizations have increasingly implemented single-use pumps in both upstream and downstream operations to comply with regulatory standards and enhance process efficiency. The region’s high volume of clinical trials and the concentration of FDA-approved production facilities have also contributed to the rise in disposable system adoption.

Government initiatives promoting pharmaceutical research and development, together with a mature healthcare infrastructure, continue to support market penetration. In addition, the heightened focus on adaptable and scalable manufacturing capacities, particularly in the context of pandemic readiness, has reinforced demand. Consequently, North America remains a key contributor to the overall growth of the global single-use pump market.

What technological advancements are shaping the single-use pumps market?

Technological advancements in the single-use pumps market have been shaped by improvements in materials science, automation, and bioprocess integration. The adoption of high-performance polymer materials has enhanced chemical resistance and operational safety. The incorporation of sensor-enabled designs has allowed real-time monitoring of flow, pressure, and contamination risks.

Compatibility with automated and closed-loop bioprocessing systems has strengthened process reliability, particularly in pharmaceuticals and biotechnology. Modular pump architectures have facilitated flexible manufacturing, while advancements in 3D printing have supported rapid prototyping and customization. These innovations have increased efficiency and minimized validation time, leading to wider acceptance across biopharmaceutical production, cell therapy processes, and sterile fluid handling applications.

Use Cases

- Media Transfer and Aseptic Sampling: In upstream bioprocessing, single-use peristaltic pumps support media transfer, buffer preparation, and closed aseptic sampling. An NCBI study indicates that almost every stage of continuous and batch workflows—from tubing connections to sample withdrawal is now enabled by disposable pump systems, which strengthen sterility and minimize cross-contamination risks.

- Sterile Fluid Handling in Vaccine Production: Single-use pumps play a critical role in sterile, closed-loop vaccine manufacturing. These systems manage high-volume fluid transfers and can achieve cost reductions of more than 60% by removing the need for cleaning and sterilization associated with stainless-steel equipment.

- Rapid Facility Changeover in CDMOs: Contract development and manufacturing organizations use single-use pumps to accelerate line changeovers. Acceptance of supplier sterility certifications reduces cleaning-validation needs and supports faster batch turnaround, which is essential for small-batch and personalized-medicine production.

- Cryopreservation of Biologic Working Stocks: Flexible single-use pump assemblies are employed to automate the filling of cryogenic bags with cell banks and viral vectors. This supports large-scale working-stock aliquoting, maintains aseptic integrity through freeze–thaw cycles, and enables efficient biobanking operations.

Frequently Asked Questions on Single-use Pump

- How does a single-use pump work?

A single-use pump operates through pre-sterilized, replaceable pump heads that handle the process fluid. The mechanism ensures closed-loop handling, minimizes cleaning needs, and allows rapid system changeovers, supporting higher production efficiency in sensitive manufacturing environments. - What are the key advantages of single-use pumps?

The advantages include minimized contamination risk, reduced cleaning validation, lower cross-product carryover, and faster batch transitions. Operational flexibility is improved, allowing manufacturers to scale processes efficiently while maintaining stringent regulatory compliance in sterile production settings. - Where are single-use pumps used?

Single-use pumps are used in bioprocessing, vaccine production, cell therapy, food and beverage processing, and laboratory research. These systems are preferred where sterile operations, rapid changeovers, and contamination control are critical to maintaining product integrity and process reliability. - What materials are used in single-use pumps?

Single-use pumps typically utilize medical-grade polymers, thermoplastics, elastomers, and biocompatible tubing. These materials are selected for chemical compatibility, integrity under varying pressures, and compliance with regulatory requirements governing sterile and high-purity manufacturing operations. - Which industries are generating the highest market demand?

The biopharmaceutical and biotechnology sectors generate the highest demand, supported by vaccine manufacturing, biologics production, and cell-based therapies. Food and beverage industries also adopt these systems to enhance hygiene, operational safety, and production flexibility. - What technological trends are shaping the market?

Technological advancements include improved biocompatible materials, automated pump control systems, integrated sensing capabilities, and higher-performance disposable assemblies. These innovations are enhancing process reliability, operational speed, and scalability in next-generation bioprocessing facilities. - Which regions show strong market adoption?

North America and Europe demonstrate strong adoption due to advanced biopharmaceutical infrastructure and continuous investment in biologics. Asia-Pacific is rapidly expanding, supported by increasing biomanufacturing capacity, government initiatives, and cost-efficient production ecosystems.

Conclusion

The single-use pump market is expected to expand steadily as industries prioritize sterility, flexibility, and cost efficiency in fluid-handling systems. Growth has been supported by rising bioprocessing activities, increasing biologics manufacturing, and the adoption of disposable technologies to reduce cleaning and validation burdens.

Advancements in materials, automation, and sensor integration have enhanced performance and reliability across critical applications. Strong demand from biopharmaceutical, biotechnology, and vaccine production sectors continues to drive global adoption. With North America leading and Asia-Pacific rapidly advancing, the market is positioned for sustained growth as manufacturers shift toward scalable and contamination-free production environments.

Discuss your needs with our analyst

Please share your requirements with more details so our analyst can check if they can solve your problem(s)