Table of Contents

Overview

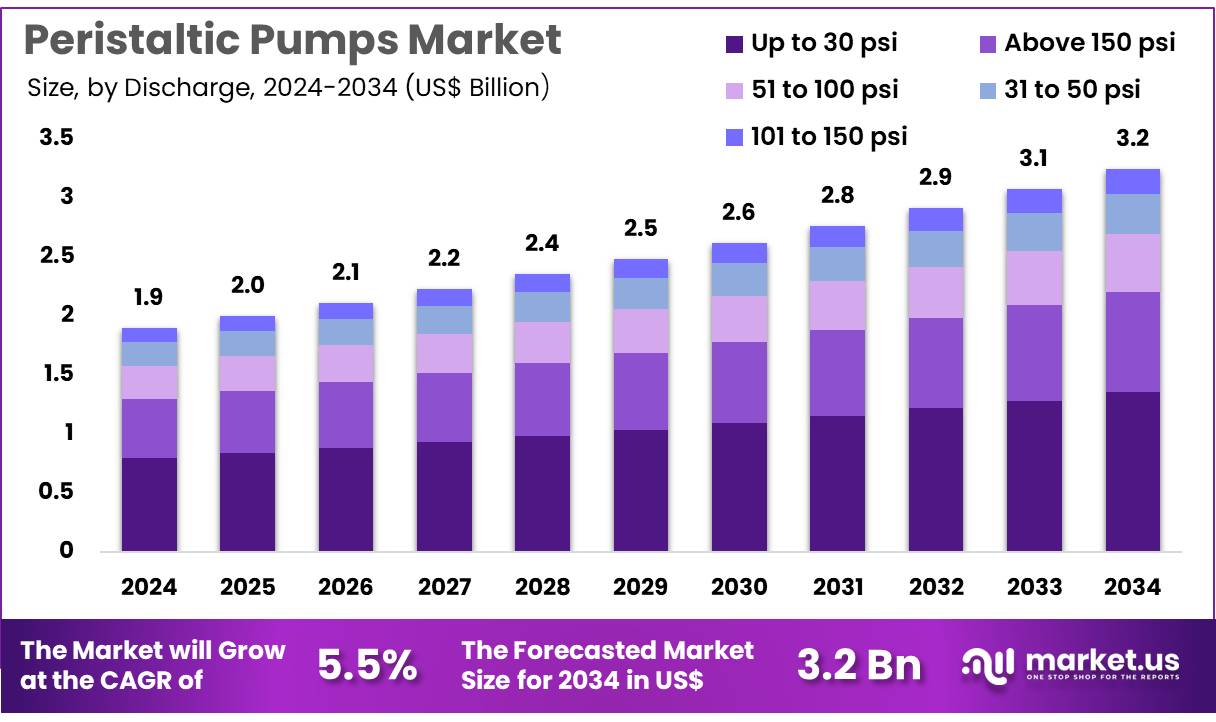

New York, NY – Nov 21, 2025 – Global Peristaltic Pumps Market size is expected to be worth around US$ 3.2 Billion by 2034 from US$ 1.9 Billion in 2024, growing at a CAGR of 5.5% during the forecast period 2025 to 2034. In 2024, North America led the market, achieving over 38.1% share with a revenue of US$ 0.7 Billion.

The global adoption of peristaltic pumps has been expanding steadily as industries continue to prioritize precision, hygiene, and operational reliability in fluid handling processes. The technology has been recognized for its ability to transfer sensitive, viscous, and shear-sensitive fluids without contamination. This performance is achieved through a simple yet effective mechanism in which fluid is moved through a flexible tube by a rotating roller system.

Demand for these pumps has been supported by increasing applications across pharmaceuticals, food and beverage processing, water treatment, and chemical handling. Growth of the pharmaceutical sector has been accompanied by rising interest in accurate dosing and sterile transfer systems. The food and beverage industry has adopted the equipment due to strict hygiene requirements and the need to handle ingredients gently. In water and wastewater management, the pumps have been used to meter chemicals with high accuracy, supporting the modernization of treatment facilities.

Industry expansion has also been encouraged by the rising shift toward low-maintenance pumping solutions. The design of peristaltic pumps eliminates direct contact between the fluid and mechanical components, reducing wear and extending service life. Advancements in tubing materials and digital control systems have contributed to enhanced operational efficiency.

Overall, the market outlook remains positive as industries seek reliable and contamination-free pumping technologies. The broader transition toward automation and precision-driven processes is expected to support continued adoption of peristaltic pump solutions.

Key Takeaways

- In 2024, the peristaltic pumps market generated US$1.9 billion in revenue, recorded a CAGR of 5.5%, and is projected to reach US$ 3.2 billion by 2033.

- The pressure-based segmentation includes tube pumps and hose pumps, with tube pumps accounting for the largest share at 56.4% in 2024.

- Based on discharge, the market is categorized into up to 30 psi, 31–50 psi, 51–100 psi, 101–150 psi, and above 150 psi, with the up to 30 psi segment representing a notable 14.7% share.

- In terms of end users, the market is classified into pharmaceutical & medical, water & wastewater, pulp & paper, food & beverage, and others. The pharmaceutical & medical segment dominated the market with a 53.5% revenue share.

- North America remained the leading regional market, capturing 38.1% of the global share in 2024.

Regional Analysis

North America Leading the Peristaltic Pumps Market

North America accounted for the largest revenue share of 38.1%, driven by broadening usage across pharmaceuticals, water treatment, and food processing. The approval of new drug applications increased by 15% in 2023, as reported by the US Food and Drug Administration, which strengthened demand for sterile and accurate fluid transfer systems in pharmaceutical production.

Federal funding for water infrastructure reached US$7 billion in 2023, according to the US Environmental Protection Agency, supporting greater deployment of peristaltic pumps in wastewater treatment projects. A 6% rise in food safety compliance inspections, as stated by the US Department of Agriculture, encouraged food processors to adopt hygienic pumping technologies.

Increased orders from biotechnology companies were recorded by major manufacturers, supported by an 8% rise in biopharmaceutical production capacity in 2023. Automation adoption in chemical processing also expanded, with the US Occupational Safety and Health Administration noting a 10% increase in automated system implementations.

Asia Pacific Expected to Register the Fastest CAGR

The Asia Pacific region is projected to achieve the highest CAGR due to rapid pharmaceutical growth and environmental initiatives. China’s National Medical Products Administration approved 22% more pharmaceutical production facilities in 2023, creating heightened demand for precision fluid handling systems. India’s Central Pollution Control Board mandated a 30% increase in effluent treatment plants across industrial zones, which accelerated the need for reliable pumping solutions.

Japan reported a 12% rise in biopharmaceutical exports in 2023, reinforcing the requirement for contamination-free transfer technologies. Australia registered an 18% increase in medical device manufacturers, contributing to demand for specialized fluid management systems. Southeast Asian countries invested US$3.5 billion in water treatment infrastructure, indicating sustained adoption of pumping systems across the region.

Emerging Trends

- Miniaturization for Microfluidics: The advancement of peristaltic micropump technology has been driven by the growing demand for compact and precise fluid-handling components in lab-on-a-chip and point-of-care platforms. Recent technical evaluations indicate continued progress in reducing overall device size while sustaining accurate flow performance at microliter-per-minute levels.

- Integration in Medical Infusion Systems: The application of peristaltic mechanisms has become widespread in infusion and dialysis equipment due to their sterility, closed-flow operation, and gentle handling of biological fluids. According to regulatory guidance, these systems are classified as Class II medical devices and are routinely incorporated into multi-channel infusion platforms for controlled administration of therapeutic agents.

- Adoption in Environmental Sampling: In environmental monitoring, the adoption of low-flow and low-stress sampling methodologies has increased reliance on peristaltic pump technology. EPA sampling protocols recommend their use for groundwater extraction at depths up to 25 feet, enabling minimal disturbance of volatile constituents during sample collection.

Use Cases

- Groundwater Monitoring and Sampling: Peristaltic pumps support low-flow purging and sampling in monitoring wells where the water depth is below 25 feet. EPA Region 4 guidance specifies this approach to limit sample agitation and reduce the loss of volatile organic compounds (VOCs) prior to laboratory analysis.

- Drinking Water Chemical Dosing: Among the 148,457 active public water systems in the United States (2020), many facilities utilize peristaltic pumps for accurate dosing of disinfectants such as chlorine and fluoride. Their metered delivery capabilities support compliance with established national drinking-water quality standards.

- Hemodialysis Machines: In 2020, approximately 808,000 individuals in the United States were living with end-stage kidney disease, with roughly 558,000 patients (69%) receiving dialysis. Hemodialysis systems integrate peristaltic pumps delivering flow rates between 5 mL/min and 300 mL/min to circulate blood through dialyzers while maintaining sterile and pulsation-controlled movement.

- Bioreactor Volume Control in Research: In CDC research test stands, peristaltic pumps are positioned downstream of bioreactors to adjust outlet flow precisely. Operating at rates as low as 0.1 mL/min, these pumps provide accurate volume control during microbial and biofilm experiments, supporting high reproducibility in laboratory investigations.

Frequently Asked Questions on Peristaltic Pumps

- What industries commonly use peristaltic pumps?

Peristaltic pumps are widely used across pharmaceuticals, biotechnology, food and beverage, water treatment, and chemical processing. Their ability to handle viscous, shear-sensitive, and sterile fluids makes them essential for operations requiring precise and hygienic fluid handling. - What are the advantages of using peristaltic pumps?

These pumps offer contamination-free fluid transfer, accurate dosing, and reduced maintenance due to minimal wear of internal components. Their gentle pumping action also protects delicate fluids, ensuring reliable performance across applications involving sensitive formulations or particulate-rich materials. - What types of peristaltic pumps are available?

Two primary types exist: tube pumps and hose pumps. Tube pumps are suited for low-pressure applications, while hose pumps are designed for higher pressures and larger flow rates, supporting industrial operations requiring robust and continuous fluid transfer capabilities. - What fluids can be handled by peristaltic pumps?

Peristaltic pumps can manage viscous, abrasive, corrosive, and shear-sensitive fluids, as well as sterile products. Their closed-tube design enables safe transfer of chemicals, pharmaceuticals, slurries, and food ingredients without contamination or damage to fluid properties. - What is driving growth in the global peristaltic pumps market?

Market growth is supported by rising pharmaceutical production, stricter hygiene standards, expanding water treatment projects, and increased automation. Industries are adopting peristaltic pumps due to their reliability, accuracy, and suitability for contamination-sensitive processes. - Which region currently leads the peristaltic pumps market?

North America leads the market due to strong pharmaceutical manufacturing, significant water infrastructure investments, and strict regulatory compliance in food and chemical industries. These factors collectively support broader adoption of advanced and hygienic pumping technologies. - Which segment dominates the peristaltic pumps market by end user?

The pharmaceutical and medical segment holds the largest share, driven by the need for sterile fluid transfer, precise dosing, and increased manufacturing of biologics and specialty drugs. These requirements strongly favor the use of peristaltic pumping systems.

Conclusion

The global peristaltic pumps market has demonstrated steady expansion, supported by rising demand for precise, contamination-free, and low-maintenance fluid handling solutions. Growth has been driven by strong adoption across pharmaceuticals, water treatment, food processing, and biotechnology, where accuracy and hygiene remain critical.

Advancements in microfluidic miniaturization, medical infusion systems, and environmental sampling continue to enhance market potential. Regional insights indicate sustained leadership in North America and rapid expansion in Asia Pacific. Overall, the market outlook remains positive, with automation, regulatory compliance, and increasing investment in clean and sterile processing expected to reinforce long-term growth.

Discuss your needs with our analyst

Please share your requirements with more details so our analyst can check if they can solve your problem(s)