Table of Contents

Overview

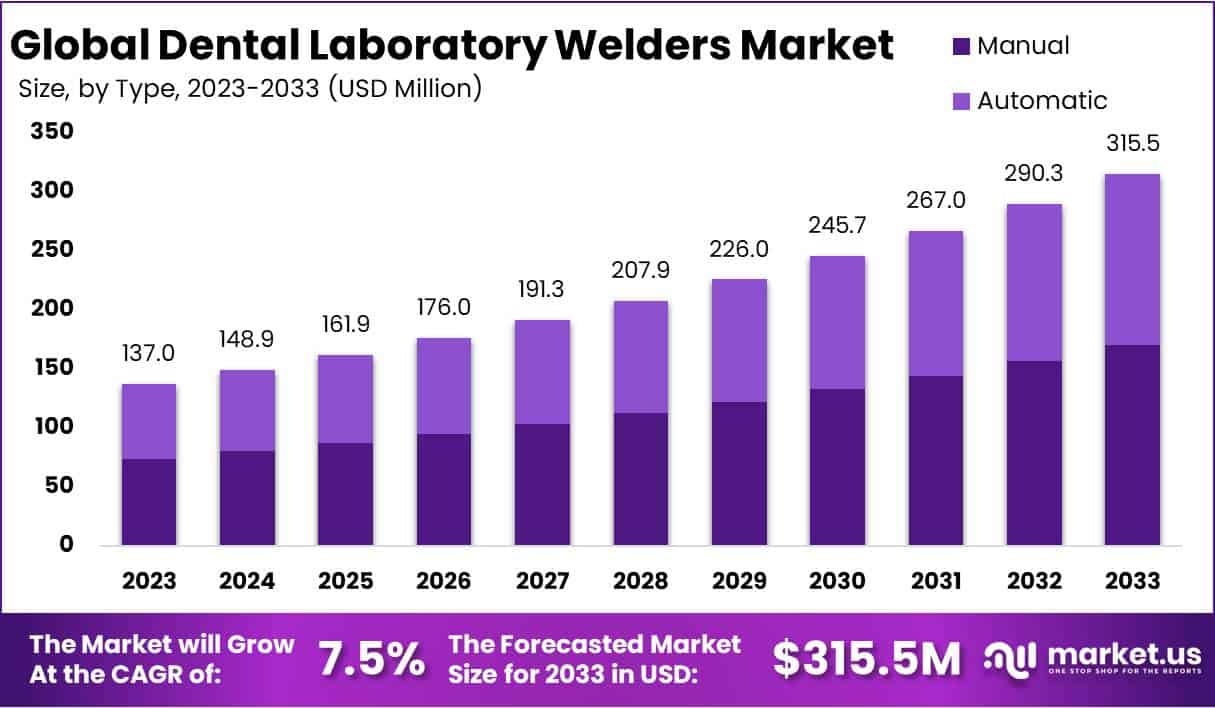

New York, NY – June 24, 2025: The Global Dental Laboratory Welders Market is expected to reach USD 315.5 million by 2033, growing from USD 137 million in 2023. This represents a compound annual growth rate (CAGR) of 7.5% from 2024 to 2033. One major factor driving this growth is the high burden of oral diseases. According to the World Health Organization (WHO), over 3.5 billion people globally suffer from conditions such as dental caries, gum disease, and tooth loss. Dental laboratories play a key role in producing restorative solutions like crowns, bridges, and implants, all of which require precise welding processes to ensure durability and functionality.

The rising prevalence of untreated tooth decay further accelerates market demand. In the United States alone, nearly 90% of adults between ages 20 and 64 have experienced tooth decay, while about 25% have untreated cavities. Among children aged 2–19, 46% have at least one cavity. These untreated conditions necessitate restorative dental services, increasing the demand for advanced laboratory welding systems that ensure high-quality results. As restorative treatments become more common, the market for specialized dental lab welding equipment is expected to grow steadily.

Another important driver is the global aging population. Oral health problems tend to worsen with age. For example, around 70% of adults over 65 in the U.S. experience complete tooth loss. This age group also has a higher risk of periodontal disease and requires more fixed prosthetics and dental implants. As the number of elderly individuals increases worldwide, dental laboratories must invest in welding tools capable of managing complex restorations involving metal frameworks and implant-supported structures. This shift is creating sustained demand for technologically advanced and high-precision welders.

Regulatory compliance and international standards also influence market expansion. ISO 13485, an international standard for medical device quality management, has been widely adopted by dental labs. This aligns with the U.S. FDA’s Quality Management System Regulation (QMSR), set to take effect in February 2026. Moreover, ISO 28319 outlines specific requirements for laser welding in dental applications. As labs aim to meet these standards, demand rises for welders that ensure accuracy, traceability, and product reliability. This compliance focus drives further investment in state-of-the-art welding systems globally.

Social and economic inequalities in healthcare continue to impact oral disease rates. In the U.S., preschoolers from low-income families are over three times more likely to have untreated cavities compared to their wealthier peers. Disparities also exist across race, education, and geographic regions. Globally, disadvantaged communities suffer a higher burden of untreated oral conditions. In response, governments are increasing funding for oral health campaigns and access to restorative care. As more patients receive treatment, dental laboratories are required to scale up their operations, further boosting the need for efficient and precise welding tools.

Supportive public health policies provide long-term stability for market growth. Initiatives like WHO’s water fluoridation guidelines (0.5–1.5 mg/L) have led to a 60–90% reduction in cavities among children. The U.S. Healthy People 2030 framework also identifies dental decay as a major chronic condition, urging improvements in access to oral care. While preventive efforts are essential, restorative treatment remains crucial for millions already affected by tooth loss and decay. This consistent need supports steady demand for dental laboratory welders used in the production of durable dental restorations.

Key Takeaways

- The dental laboratory welders market is expected to reach USD 315.5 million by 2033, reflecting a strong CAGR of 7.5% from 2024.

- Manual welders dominate the market with over 54% share, contributing USD 74.1 million to global revenue in 2023.

- Manual welding techniques remain widely used, accounting for over 40% of the application segment and generating USD 54.8 million in 2023.

- Cosmetic dentistry is growing rapidly, projected to reach USD 145.3 billion by 2033, supported by a CAGR of 14.2%.

- Digital workflows and CAD/CAM tools are transforming labs, with nearly 60% of dental laboratories adopting these technologies by 2023.

- North America leads the market with a 36% share, amounting to USD 45.7 million in revenue in 2023.

- Asia Pacific and Europe are emerging as strong contenders, driven by technological progress and increased regional investments in dental innovation.

Emerging Trends

- Laser Welding Gains Dominance: Laser welding is becoming the most preferred method in dental labs. It offers high precision, minimal heat damage, and clean joints. This method is now widely used for dental alloys such as cobalt-chromium and titanium. These materials are common in crowns, bridges, implant frameworks, and orthodontic parts. The laser process ensures durability without altering the metal’s properties. As a result, dental technicians increasingly rely on laser systems for both standard and complex restorations. The ability to perform fine micro-welding without affecting adjacent structures makes this technique ideal for high-accuracy prosthodontic work.

- Integration with Digital Workflows: Dental welding is now part of digital workflows in many labs. CAD/CAM systems and intraoral scanners provide design files directly to welding units. This integration simplifies production and reduces the manual steps involved. With fewer errors and faster output, labs are achieving better efficiency. The digital-to-physical transition becomes seamless. This trend supports the growing use of digital dentistry, especially in custom-fit prosthetics. As 3D design becomes more common, the ability to weld directly from digital plans ensures consistency and saves valuable time.

- Automation and Smart Systems: Welding units now come with advanced automation features. Robotic arms, AI-assisted positioning, and automatic parameter settings are being added. These technologies reduce human error and speed up production. In large dental labs, automation helps maintain output consistency across many cases. AI helps adjust settings based on the alloy and joint type, improving welding quality. Smart systems also collect usage data for maintenance and performance tracking. With increased case loads, automation ensures labs can meet demand without compromising precision or material strength.

- Eco-efficient and Compact Equipment: Modern dental welders are smaller and more energy-efficient than older models. Many are compact desktop systems that fit in limited lab spaces. They consume less electricity and use shielding gases more efficiently. This makes them more cost-effective and environmentally friendly. Their compact size does not compromise performance. These systems still deliver the accuracy needed for detailed dental work. As dental labs aim to reduce overhead and energy use, demand for such eco-efficient models is increasing. This is especially true in midsize and urban labs with space constraints.

- Expanding Use of Biocompatible Alloys: Titanium and cobalt-chromium are now widely used in dental restorations. These metals are biocompatible, strong, and corrosion-resistant. However, they are sensitive to heat and can be damaged by traditional welding. Laser welding solves this issue by offering low-heat processing. This method preserves the alloy’s integrity and improves the final product’s durability. Dental labs are adopting laser welding to meet the demand for stronger, safer restorations. As patient awareness of biocompatible materials increases, their use in crowns, bridges, and implants is expected to grow rapidly.

- Adoption in Orthodontics and Implant Prosthodontics: Laser welding is expanding into orthodontics and implant prosthetics. It is now used to produce precise intraoral connectors and orthodontic components. The process creates strong, accurate joins that hold up under oral stress. Case studies show that laser-welded parts offer high material strength and safety. This is important in procedures that require long-term durability, such as fixed implant bridges. Orthodontists and implantologists increasingly prefer laser-welded components due to their accuracy and patient comfort. The trend shows a clear shift toward high-performance custom parts across dental specialties.

Use Cases

- Crown and Bridge Repairs: Laser welding is widely used for repairing crowns and bridges. It allows precise joining of components without heating or damaging the ceramic structure. This technique has helped dental laboratories reduce case turnaround time by about 25%. The main reason is that it eliminates two manual processing steps that are usually required in traditional soldering. The process is cleaner, more efficient, and offers better control. As a result, crown and bridge assemblies are completed faster, which leads to improved productivity in dental laboratories and shorter waiting periods for patients.

- Implant Bar and Connector Fabrication: Laser welding is used in the fabrication of implant bars and small connectors like posts or loops. The technique delivers precision with sub-0.1 mm accuracy. This high level of accuracy leads to fewer post-fabrication corrections. Clinical and lab reports show a 15% to 20% reduction in adjustment needs. The improved fit ensures better patient outcomes and reduces rework for dental technicians. This results in lower overall costs and faster delivery times for implant-supported restorations. It also enhances long-term prosthetic stability.

- Orthodontic Appliance Assembly: Orthodontic appliances often require welding for wire components and frameworks. Laser welding supports the assembly of custom mini-implant abutments and 3D-printed parts. In one clinical case involving a 15-year-old patient, laser-welded implant components maintained their exact alignment over the entire treatment period. This showed that laser welding offers excellent structural integrity. The method also allows precise customization of orthodontic appliances. It reduces the risk of misalignment and increases the success rate of long-term treatment plans.

- Repairing Clasps in Partial Dentures: Laser welding is used to fix broken clasps in partial dentures, especially those made from cobalt-chromium alloys. Dental labs can now repair over 90% of damaged clasps in a single session. This eliminates the need for outsourcing and reduces the wait time for patients by nearly half. The process is quick and eliminates the multiple visits usually required in traditional repair workflows. It also maintains the structural strength of the original denture. For patients, this means fewer disruptions and faster resolution.

- Intraoral Implant Welding: Laser welding can be performed directly in the mouth in specific implant cases. It is used to link titanium implants or abutment parts during surgery. The procedure improves the initial stability of the implant structure. Compared to conventional mechanical linking methods, it also saves chair-time—by approximately 30 minutes per case. Dentists benefit from easier handling, and patients receive quicker procedures with reduced discomfort. This technique is particularly helpful for immediate loading or in cases where fast stabilization is required.

Conclusion

The dental laboratory welders market is growing steadily due to rising oral health needs, aging populations, and increased demand for restorative treatments. As dental conditions like tooth decay and tooth loss remain common worldwide, laboratories are adopting advanced welding systems to produce accurate and durable restorations. Laser welding, digital workflows, and automation are transforming lab operations, making processes faster and more reliable. Growing awareness of biocompatible materials and international quality standards is also driving equipment upgrades. With supportive health policies and improved access to dental care, the need for efficient welding tools will continue to rise. These trends ensure strong market momentum in the years ahead.

Discuss your needs with our analyst

Please share your requirements with more details so our analyst can check if they can solve your problem(s)